-

Posts

286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Gallery

Community Map

Everything posted by leener

-

Nothing exciting. Just a bit of engine cleaning in advance of the weekend. Plenty to do. Lots of nasty old gasket getting removed.

-

I'm dreading my renewal. I insured my Sprint 955i last April for around £250. I had to have my ZZR600 policy cut short, because the insurer wouldn't cover me on such a huge beast of an engine as the 955i , with it's extra whopping 20hp. I'll find out what my renewal cost will be in the next month, or so. With all the spate of thefts in the area, I'm guessing that it'll be the equivalent of a mortgage. One guy had three quotes on CompareTheMarket. The rest wouldn't cover him, this year. The cheapest was £450, all the way up to £4k

-

I’m only assuming that it’s normal. I never had any issues with this before, and can’t see any sign that the clutch was opened and attacked by a rabid dog. I wonder how many other engines have these marks on the clutch. First time I have ever had an engine open to this degree, so I’m spotting all sorts right of interesting stuff... like a B on the back of the piston rods.

-

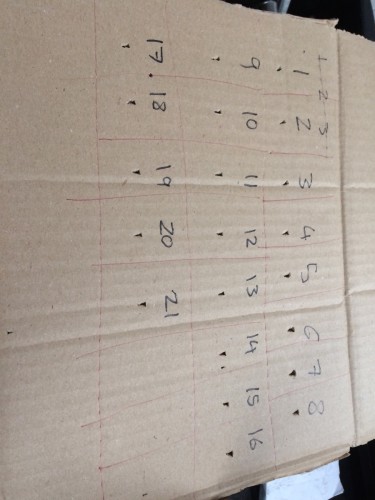

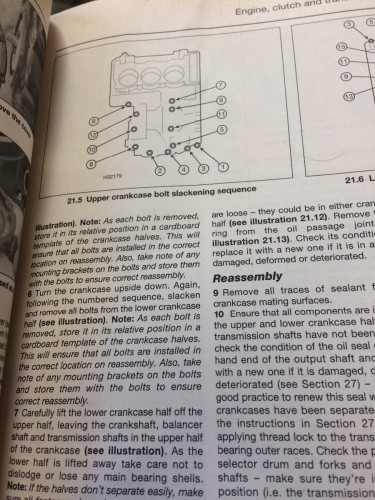

Cheers, mate. Good idea. I need to give one more look over and teat (TEST - my phone always autocorrects to “teat”) for leaks, and try to re assemble the engine, before doing another compression test while the lump is in the garden. I hope that I can suss this without cracking into the bank too much more. I tell you what mate, your bolt keeping method is spot on. When I did my ZXR I just chucked everything in a magnetic tray and trusted my memory. Cheers . I’m trying to be as organised as possible. I spent 30 minutes looking for the bleeding metal o-ring from the balancer shaft, what’s it called, only to find it had fell into my toolkit. Not much space to work in, in a metal shed.

-

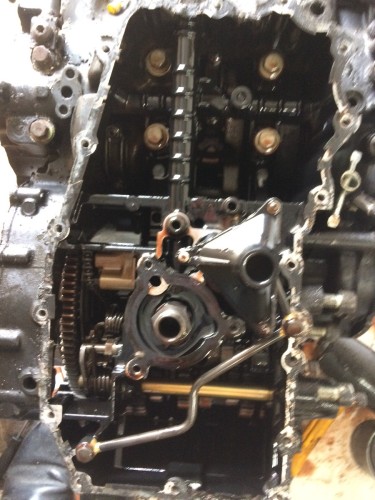

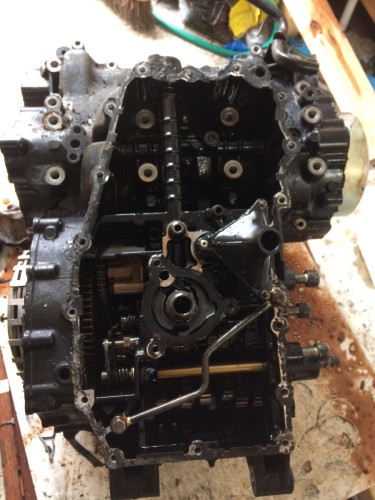

I have been cleaning up the the top and bottom halves of the engine to get rid of vast amounts of dirt, mud, and caked up oil. The paintwork on the engine is not great, but I’ll cover that up. I managed to extract two stuck half-bolts that had sheared off, on the stator cover port, and sanded (gently) the old gaskets off. Some more to do, but making good progress. I’m going to do more investigation, but noticed a lot of grey sealant had got into the head gasket, which I must have ignored prior to fitting. Some had blocked one of the holes for the coolant, which teaches me to take my time and work cleaner, in future. The work goes on...

-

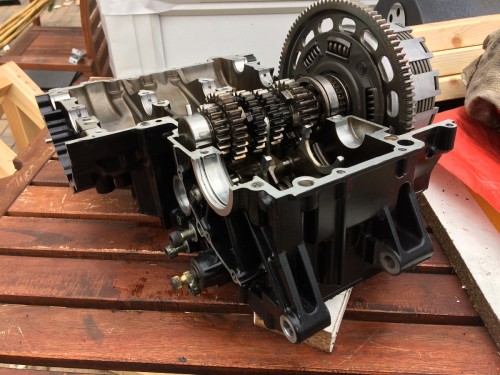

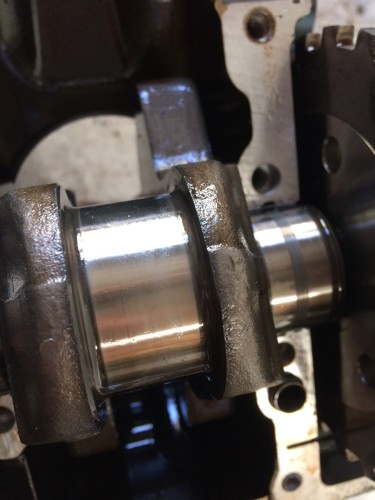

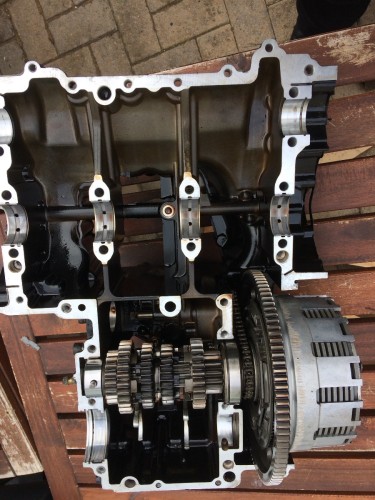

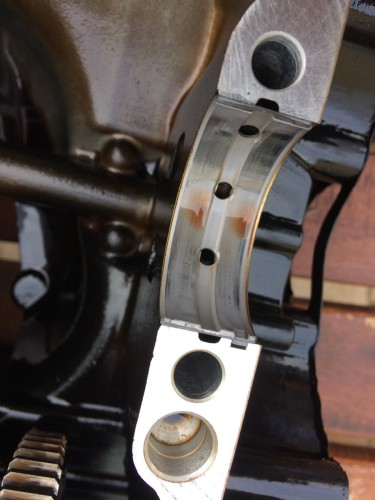

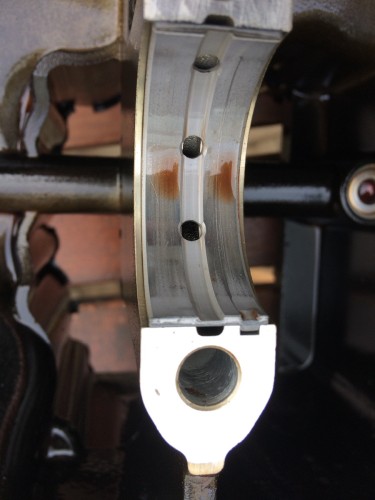

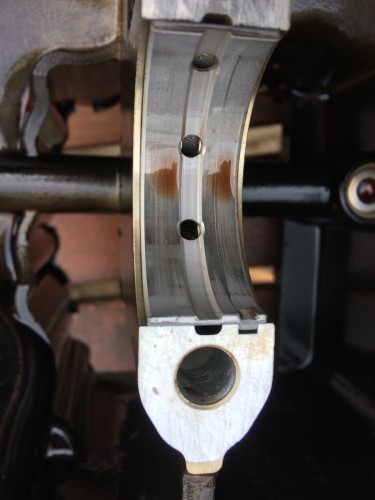

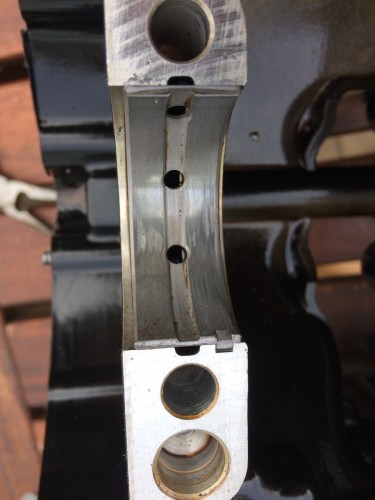

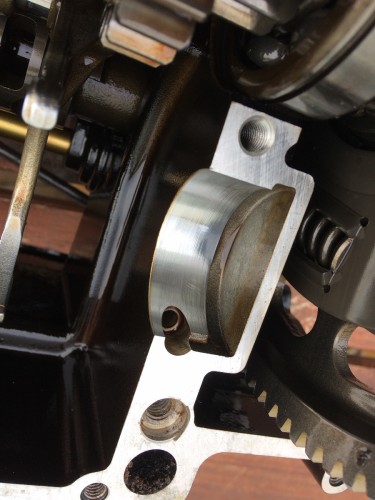

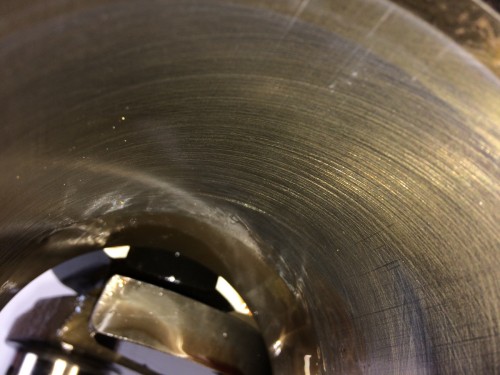

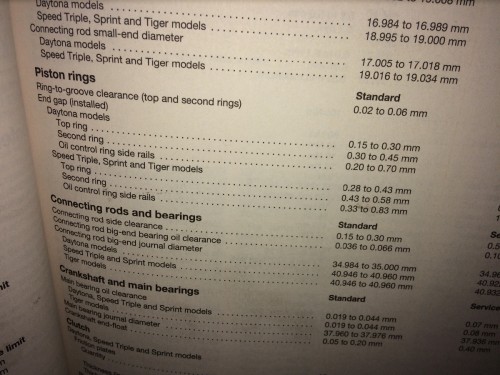

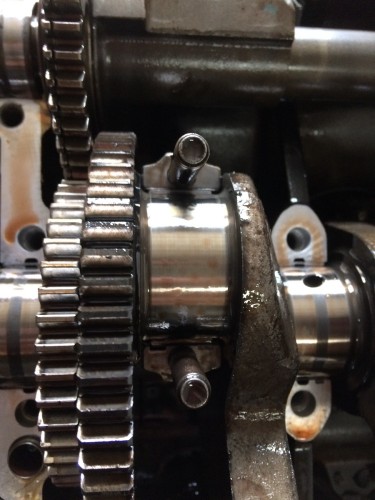

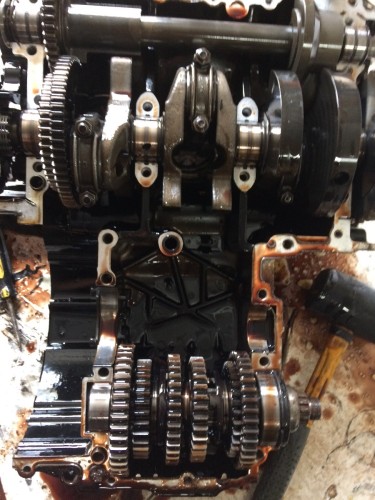

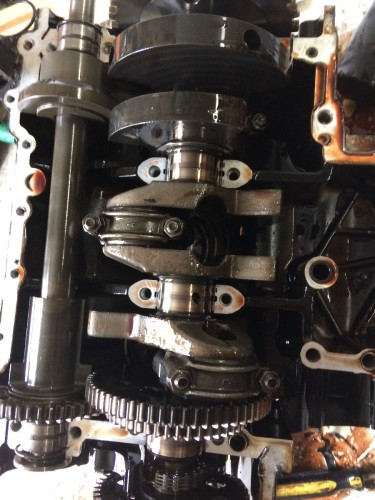

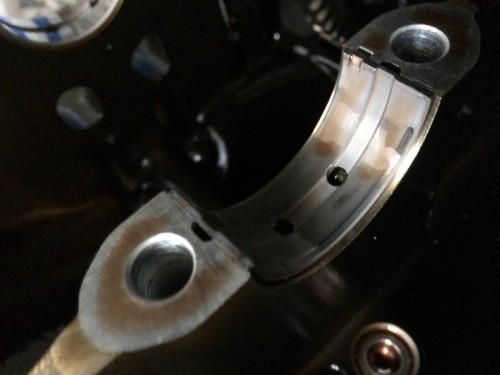

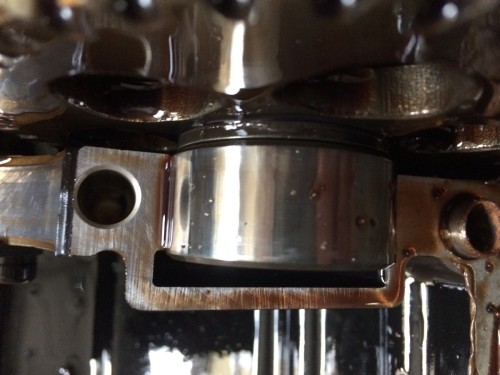

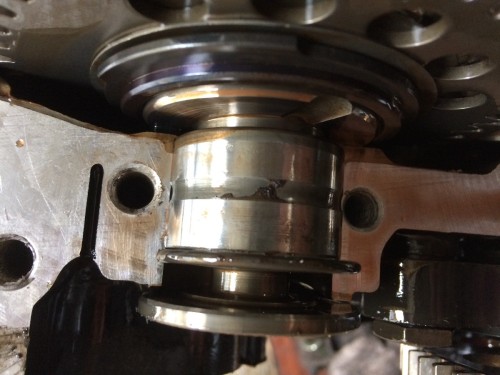

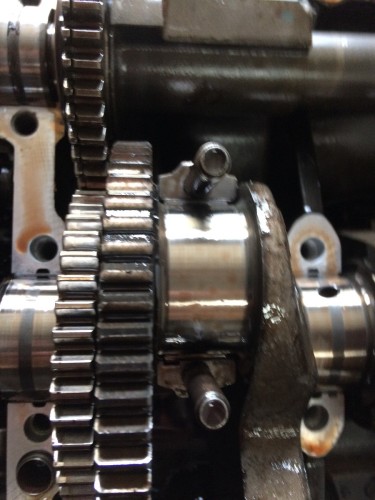

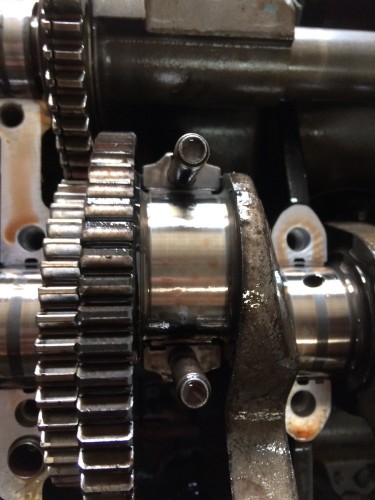

All rings in spec, big ends clearance is fine and in spec, so all seems ok. Here are some pictures, however. Scoring is present, but not excessive. The clutch housing has some serious marks from some trauma. I may have to have a think about what steps to take, next. The bores were a little scored, but the diameter was the same all down. I carefully pushed a ring down all the way and checked each inch to see if the gap was always the same. No idea if anyone else tried this, but it is the best I can do with what little tools I have. I am now being asked... or told to go take father in law to the shops so he can get his obesity prescription of sugar filled crap. Being the only able bodied person has its problems, because certain individuals are too lazy. I need to finish this engine, but can’t to much else until the gasket kit arrives. As it is, the low compression is not looking to be due to the pistons.

-

Woohoo! Just won a gasket set for my engine on eBay for £1.75 + shipping. Saves me a few quid. I will get started in a little while, on piston 1. Caffeine not kicked in, yet.

-

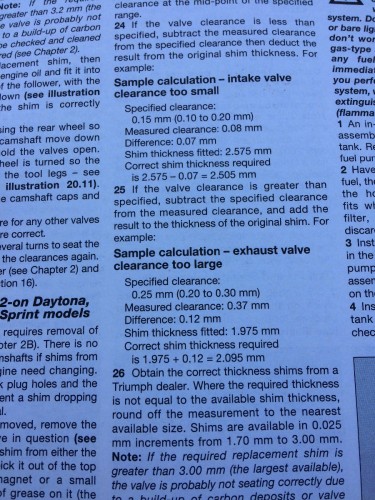

Cheers, guys. Hope I don’t sound dumb when I ask about clicking the big ends, and what it means. I don’t think that I did this. I did as fastbob described, and it was also mentioned in the Haynes manual, that you put the rings into the bore to get the end gap measurement. I took my time and did the best I could. The pictures were for show, but I did push the rings about an inch deep into the bore. I did exactly as the manual said (only done cylinder three, today) and checked thoroughly that the rings were smack-bang right in tolerance. I checked the piston diameter and that was also in tolerance, according to the Haynes bible. I gently compressed the rings onto the piston, and eased the thing back into the bore, having to make sure that I put it in the right way round! I have my technique right to do it only using my fingers. I’m tired out and bitterly disappointed that I can’t find an issue with the rings, so far. I have the other two to do tomorrow. The low compression is a big problem, and I am going to check the valves again, and consider that I could have got the exhaust and intake cams mixed up. But, if I did, then wouldn’t there be significant signs of bent valves? Off to build a cot, now. All your advice is greatly appreciated.

-

-

-

Whilst I was messing around on Facebook, I saw a post popup, by some guy in Canada, on a Triumph Sprint ST 955i owners group. He claims to have thrown a 1050 lump in there, managed to wire it up and changed the starter motor for the newer model, and it fired up. No idea if it was rideable, because there was too much snow where he is. So, I wanted to follow up on that one. Not that I intend on buying a 1050 engine, but it is still interesting. Once I get all my findings, I will post them up here and hopefully can come to an easy decision, based on the advice. Interestingly enough, I have the standard Triumph Sprint 955i maintenance manual for the model with the older engine in, and that had bore liners. You have to access from underneath to get them out. I'll ask Lord Haynes, when I get a chance - hopefully tonight (I'm at work.. don't tell the boss!).

-

That's why I held off paying and ordering and ordered a new micrometer from ebay, instead. You gave me tons of great advice for this step, so I am getting prepped for the weekend, got my Haynes manual, and ready to get to work. If I am going to spent £180, I want to make sure that my investment is necessary, and there are no other issues. I will be taking plenty more pictures and recording each finding, as I deconstruct the crank case and pistons, and inspect everything, as per the manual. It is the best way for me to learn. The deeper into this, I get, the more inclined I am to want to keep hold of the bike. That was a conversation that I was having with mate from work, earlier. The fact that you can shift the parts for £150 here, £50 there, another £50 here, ends up with you potentially having more than enough left over for a good replacement lump, which works. I have already been scouring the sold items on eBay to see what the components are worth. At the very least, I want to get stuck in with this inspection, and go from there. This is experience that I will benefit for a lifetime.

-

Fortunately, Sprint Manufacturing are UK based, so postage is £4.95. I can't remember who recommended - have to look back in the thread. This, by far, is the best price that I can get, to my research. I ordered a micrometer and found a lower gasket kit for ~£15 on fleabay. The engine is all in bits, in the shed, waiting for me to get round to finishing opening the crank case. Hope there is room in the dish washer...

-

Just made my first discovery... £176.52 for three sets of piston rings. http://www.2wheelpros.com/oem-parts/triumph-ring-set-79-0-cast-piston-t1120865-part.html Sprint Manufacturing have supplied virtually all the components that I have so far needed in this project, and even doing a little digging around has revealed that this will be the cheapest likely price that I'll find the rings. Not to mention, I also need to think about gasket kits... And they aren't cheap, either! Surely, there's a cheaper way to manage this. Gasket paper and a careful hand seems to be an option, but also, have issues with paint flaking off the engine casing. This is turning into one heck of a job, but still a lot cheaper than if somebody else did it for me.

-

Finished up for today since a 10am start on a Sunday is a bit of a long “day of rest”. Today I: Removed engine Removed cylinder head Checked valves for damage Realised that the cams were on fine (thanks fastbob) Removed engine side covers Cleaned up disgusting case Found CORRECT bolts for side of cylinder head on floor of shed (see earlier posts) Removed crank case bolts Started trying to loosen crank case halves Packed up I aim to do more work on it during the week, after I eventually get home from work, and read more about the deconstruction of the crank case. I have done a lot of research on piston rings and know what each one is for, and why the gap size is crucial. Looking forward to the next part.

-

-

-

Ah, that makes sense. The cylinder bores are entirely integral to the crank case. Penny pinching, indeed! Everyone is at it. I took a break and had my sandwich, and now off to the shed to crack her open. I made a sledge-like platform to get the engine round the back garden. But, to get it round, I had to drag it through the snow on the public footpath, and through the neighbors drive, to reach the side-alley. People must have though I was going sledding with my engine. You know, like all the cool kids do. Back to work...

-

Guys. I made a massive mistake. I didn’t check before I put the cams back, that the engine was at true TDC. In fact, it was all wrong! I checked by setting it to T1, then saw that both cams had the arrows perfectly aligned... pointing outwards!!! How? How did I screw that up? By not checking thoroughly, working when tired, and without correct lighting. Luckily, no valves are bent and there are no markings on the tops of the pistons. I got away with this one, but it certainly taught me a lesson. The oil was absent from the pistons, as I saw when removing the head. But, a lot of an unknown liquid was pooled up... How badly would this mistake affect compression? I’m going to say, A LOT. But, please correct me. I am still learning. The crank case is still 100% together and waiting to be opened up, after I clean it up. Is it still looking like a piston ring set is necessary?

-

Back from a short holiday, due to "adverse" weather conditions. We were in Bideford until the red weather warning on Thursday, and then I decided to drive back to Bristol, which was nothing short of a deadly, four wheeled ice skating trip from frozen hell. The ABS was always kicking in, and the snow got far worse by the time we reached the house. I made a good decision, because one stretch of road we used was reported to have had a lot of stranded vehicles overnight. Still, it was actually rather fun, and I even squeezed a couple of cheeky handbrake turns in, to get my car round the corners. Naughty! Today, I decided to pop the engine out, even in the snow, which is now rapidly melting. Tank, exhaust, throttle body, and everything off, including front sprocket. All six engine mount bolts painfully extracted (the bottom two were a bit of a nightmare), and expected the engine to require a few knocks to drop down onto the little trolly that I constructed in the garden, specially for this job. Would it come out the frame? Would it duck! Totally jammed in there! It has moved forward as far as it can, and it is down by around 1cm, but nothing is holding it, other than the tight frame. The whole lump has moved, so can't be any more bolts. I don't want to damage the casing, so tried blocks of wood and a mallet. I am at a loss. And it has started raining... Typical. Maybe get this out tomorrow and have pictures to show the progress of, once again dismantling the engine, but splitting the crank case open. Maybe.

-

I have had enough trouble developing software. My mechanical skill, prior to this was virtually just down to taking out a sump plug. The bike was suffering from poor starting, gradually getting worse, and blue smoke appeared for the first few minutes on start. In the beginning, I attacked the fuel map system. Being a software guy, I understand that bit very well. But, really should have understood that my knowledge of fuel/air and engines would have really improved my success, even here. With help of Tango, I cracked it, and found the correct fuel map. The original owner had botched it. But, alas! No such luck! The problem persists. I ran out of fuel on the M5 a few months before, so MUST be the fuel pump. I purchased a fuel pump and installed it. That was a great deal of a learning curve, in its own way. Still, the problem continues. Then, I realised that, with the invaluable experience and advice of members, such as fastbob, Tango, SlowBusa, and especially megawatt, that the problem with the bike was far from what I thought. With a basic level of understanding of how my engine works, it made perfect sense. Engines are by no means rocket science. They are simple, in principle... Air, fuel, spark. It's the components in between that you need to understand. Blue smoke and bad start equals? Burning oil. Where does the oil come from? Well, it is being pumped out of the exhaust, which is attached to the combustion chambers. Oil doesn't live in the combustion chambers, so how is it getting in? There are two ways: valves and pistons. So, anyone reading this with no clue, and has just found this thread via a Google search, can know that it is entirely possible to deal with this, without having to resort to scrapping the engine, or giving your local mechanic a holiday to Barbados, just for fixing your old bike. I am totally optimistic, after carrying out a full restoration of the top end, replacing the valve seals, lapping, and cleaning off burnt carbon, that replacing piston rings isn't going to be a major issue. At least now, we know that the problem is not up top, but down below - but those valves were a Mess, and the seals needed replacing. The top end work was absolutely required, and wasn't hard at all. The first valve was a bit awkward, but I quickly found that I could get into a routine and do each valve systematically. It's okay and not that hard at all. I need to work hard, yes, but I am not shy to do my dirty work, and enjoy every moment. I wear my oil with pride. This is one journey that I will see to the end, and even if it takes all year, I'll fix this thing and have it running like new. I can't see myself selling it. Holiday tomorrow, until Friday. When I'm back, that engine is coming out and into the shed for the next stage of work. Pictures and details to follow in the next saga. Night, all

-

Cheers mate. I’d appreciate that and PayPal you over the cost. I need to brush up on the procedure to get them out. Going on holiday for a week, so my plan is to get that engine out next Saturday. Going to be a lot of effort, getting that round the back and into the shed.

-

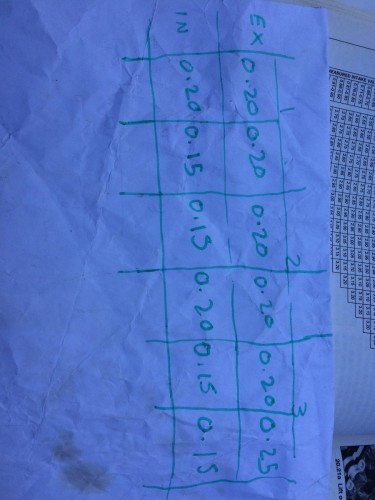

Cheers, MW. In conclusion to our chat, I have a full understanding of what comes next. Pistons are coming out next week for inspection and repair. Wet compression was as follows: Accidentally added WAY too much oil (a real squirter) to cylinder 1: Dry cylinder 2: Wet cylinder 2: Dry cylinder 3: Wet cylinder 3:

-