-

Posts

286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Gallery

Community Map

Everything posted by leener

-

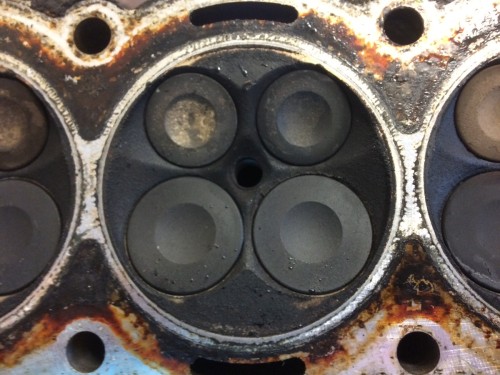

Cheers, all It’s rough as ass on top of the pistons, with burnt on deposits. And the valves are very sore. I have used carb cleaner and WD40 for the most part, and getting there. I gave up on the pistons since it started hailing, despite the met office saying <5% chance of rain. Well, hail isn’t rain... Here’s the so far;

-

I got the head off, which is now in the kitchen. There’s some carnage: Just tried scrubbing the pistons, without damaging the walls. Am I taking on too much here? Any advice on cleaning? Hoping I can find a magnet to get these bloody valve shins out.

-

There was another guy on another forum (several years ago) who acted exactly the same, and incidentally "customised" bikes. As in, totally ruining them, in the most bodgeristic way possible. People were trying to help him, and most gave constructive criticism. The whole forum ripped him to bits, after he started giving attitude. Then, he made a big song and dance about leaving the forum. I think it was a Kwak forum and possibly the same guy.

-

Oooh, young man!

-

This is a wonderful thread. The opening question was questionable, at best. Followed by an aggressive response to a logical statement... He was definitely going to butcher that poor bike. Reminds me of the guy who stabbed his oil filter to bits with a screwdriver because it wouldn't come loose.

-

I have very much found out. It was supposed to be a difficult job, but didn't expect to break my poor tool. I wasn't even going that hard, either! (That's two innuendos) I lucky to get the end out, after it broke. (That's three) Luckily, mother in law taught me a few new tricks... (potentially number four, and a total wrong-un) By rubbing your screw driver against a magnet, you can magnetise it, thus making it easy to extract the snapped off torx bit. New impact bits should arrive any day, now. I will get straight in there, this weekend, pending the weather... which is due to be abysmal.

-

Ordered a new Voche 40pc set, which I hope do the trick. Halfords would have been a good idea, too. Also ordered three exhaust gaskets and CCT gasket. Hopefully that is all I need. If all arrives before the weekend, then I'll attack the Triumph with new tools. The set that broke were brand new from the local Motaparts store, purchased about a year ago. I'm only just putting them to use and they snap, just trying to get a cylinder head off.

-

Cheers, fellas. A quick recap of why I'm doing this insane job with little or no mechanical skill: Bike goes to start and struggles to catch. There is fuel, but the spark isn't quite there. There is clearly oil getting into the combustion chamber. When it eventually starts, it blows blue smoke and really grumbles about being revved hard for a while. Middle cylinder gave the highest compression reading, by far. It just so happens that the middle exhaust port shows definite wet oil on the valve stem. It was joint effort, me and my missus. I was still coughing and had a banging headache, while she is half way through the pregnancy, so she's not allowed to do anything intensive. But, she insisted on getting stuck in with helping remove fairings, bag up the cams and bits for me, and other things, removing the muffler, like hold up the cam chain on a shoe-lace. She's a keeper, my lady. I am lucky to have her. We started at about 11am, and finally finished at about 5pm, now my legs ache like when I used to actually train them. Can't wait to get the head off. I think there is enough clearance to do it without dropping it out the frame. What do you think? The tools I used were just awful. Not fit for purpose. I am quite sure we got a little beyond 120nm before it snapped. Oh, well. Has anyone got a suggestions on strong-ass tools that can take on cylinder head bolts? And good, strong sockets that won't destroy themselves by taking the bolts out of the ladder, and such? I ruined three of my 8mm sockets.

-

Coolant already done. Spark plug 1 was caked in oil. Spark plug 2 wasn't fantastic, but ok... And number 3. Not bad. Time to get the cylinder head bolts out... Researched torque sequence on triple engines, and started with my big torque wrench and star-shaped thingy-majigies to get the bolts out. First bolt untorqued... Go to do number 2 and then suddenly... "OOOH, FUP!" Luckily, we could extract the broken off bit from the cylinder head bolt. Gave up and wrapped her up, in the end. So, need some half decent and STRONG tools to finish the job. Have to wait until they arrive. Gutted. Not even got the head off.

-

Evenin', all. Today has been a fun one for myself and my lovely lady... And the bike. The damage so far is that I have stripped it down to the head, removed rocker cover, cams, chain, the cct, and a load more, including cleaning the filthy bugger. Here are some lovely photos to tell the tale. It didn't end well. Bike is ready for a good seeing to. Taking the pulse. Bit by bit... Off comes the tank. Ooh, err. Get your airbox out, baby. Bit more, love. Finding oil on things that shouldn't have oil on... Get the fairings off. Clean rust off the chain and made the wheel not black by removing several mm of crud. Bike flashing her ladder at me. Get the ladder off. Having a play with the cams. How weird. Someone has been gouging dates into parts at the factory. 126? Valves all numbered up, ready to remove. Exhaust off. THAT WAS A NIGHTMARE! And, this was the offender. Need to find some new manifold bolts and gaskets. Now for a peek into the exhaust ports: Cylinder 1. Cylinder 2. Cylinder 3. Not looking good. More to follow...

-

Dude... You replaced the carbs, three ECU's, rectifier, plugs, and the leads? All of that? Had you done any tests on these first? And, have you checked the coils for correct resistance, according to the Haynes manual? Only things I can think of that will prevent a start, with the old Zed, are: Plugs badly burnt or soiled, Leads damaged, Coil failure, ECU/CDI failure, Air filter totally clogged, Breather hoses clogged, Fuel ways blocked or damaged, Carbs have blocked jets, floats, needles obstructed, Earth / wiring problem My zed had serious issues with the electrical wiring. So I stripped it and sold the parts.

-

I wanted to, but if I could have pushed past the epic pain in my skull and Niagara Falls of dark yellow phlegm, then the abattoir of liquid bum would have got in the way. Forgot to add that to my list of woes. This weekend, I'm determined to do it. I want to film the whole thing and clearly demonstrate my ability to bodge. The head gasket arrived! It's very strange. The whole thing is made of metal with three layers, and some sort of rubber bushing around the cylinders and ports... I'll take a photo when I get home.

-

I'll have the two Halfords 2T jacks / supports at the rear, one under each of the swing arms (didn't triumph do a single sided swing arm?). I was supposed to borrow my mates trolley jack and get the bulk of the work done, this Saturday, just gone. But, as luck would have it, I came down with the most violent case of snot, migraine, coughing fits, bleeding nose (from sneezing and excessive snotting), crying in pain, stuck in bed, not eating at all, and getting annoying at having yet another instance of death-flu. So sick and tired of being sick and tired. Why do people inflict their nasty plague on others? So, now I am back in the office, not snotting as much as before, and feeling miffed because the whole weekend just disappeared. I haven't even taken the cover off the bike in over a month.

-

Plenty of wood in this house... Mother in law builds and sells masses of IKEA furniture... It's a warehouse of a house. I ain't kiddin'! I have two car jack-stand thingy's from Halfords for the swing-arm, and I'm going to borrow a friend's trolley-jack. Budget is tight (thanks to child maintenance and my ex trying to rinse me), so I'm doing my best to keep it as inexpensive as possible, until I am financially back on track. I have a litteun on the way, so hopefully the sale of a working Triumph might help me out getting a car that isn't dependant on Kawasaki parts I'll go pester the mother in law for a little gazeebo (or equivalent) to use, seeing as her entire garden is full of them, which are all full of IKEA wood! I have no doubt that this will take several days to fully complete. I'll lose a collet or find that I need another tool, or something. The engine can be lowered down and out, using the trolley-jack, and I can work on it under a cover, if I can get one sorted out. Hopefully, videos and pics coming soon...

-

I'm liking the tips. I will first try to remove, or see if it is possible to remove the head while in the frame. But, if I can tilt it down then I will go for that. Hopefully it won't be too obstructed by the forks, or the wheel. I have the valve extractor kit but no head gasket, yet. Still awaiting delivery. Counting down to the 27th, but the nearer we get, the more the weather report changes to say that there is likely chance of rain. I plan to try and video the work so I can document it on here for everyone to see. That way, as I am not a trained mechanic (all my knowledge comes from here and YouTube), I want to show other people with no skill that they can save a few quid (or thousand) by getting their hands a little bit dirty. And, hopefully it will be a success!

-

I like to play a game when I'm out and about. The game is called, "Count how many cars are queuing behind the cyclist". My best score was 78, down a country road.

-

If you insist on taking it to a garage then, like fastbob says - take it to another. They're obviously not bothered to help you or are a bunch of idiots. If you want to resolve by yourself then get familiar with the fun of diagnosing mechanical problems. Poor running could be from a million different things... That's an exaggeration. Start by asking yourself if anything has happened to your bike, like filled up at a petrol station that looks like from the movie, Texas Chainsaw. Do basic checks like air filter, spark plugs, battery. Did the bike run properly again after some minutes or is it still running crap?

-

I hope that my lovely lady will be so kind as to take the pics for me, as my hands will be greased up bad. The first lot of stripping down will be easy and only takes me about 10 minutes to get the seat, tank, and airbox off. Plugs take a couple of minutes, taking fairings off will be about 10 minutes, so that lot is pretty simple. I've already had it apart enough times to do it blind folded. It's when I get down to the messy stuff, like getting coolant drained, removing the rad, taking the exhaust off, and getting the engine out, that the progress starts to slow down. I will more than likely need to take the whole engine out. I should replace all of the bolts around the stator cover, because a couple sheared when I replaced it a few months ago. No idea where I'm going to keep all the bits...

-

It has to be done. If I could sell it on as it is and still got a good price, I would feel too bad for whomever is the new owner. I couldn't sell it without disclosing the full picture, so would never get a decent price. So, eventually, the rain will stop and I will go out into the wilderness, armed with my toolkit. By the end of the "dry" day, I hope to have all this done: [list=]Seat off. Battery disconnected and out. Rear fairing off. Tank disconnected and off. Front side fairings off. Coolant drained. Oil drained. Oil filter removed. Radiator disconnected and moved out of the way. Belly fairing off. Exhaust off and gaskets thrown away. Coolant pipes removed. Electrics disconnected. Rear wheel loosened and brought forward, to slacken the chain. Front sprocket cover off. Chain removed from sprocket. Spark plugs out. Fuel rail disconnected and removed. Throttle body removed. Checked clearance around top of engine to see if possible to remove head while in frame, and probably decided 'nope'. Engine support bolts loosened. Jack positioned underneath and lowered engine down. Removed rocker cover. Removed head bolts. Removed head and carried into the kitchen. Convinced mother-in-law that it won't be there long... Cleaned up around bike and put the bike parts away, safely. Baring in mind that this will all be done on a driveway, behind two cars, out in the open, on a bike with only a side stand. This is going to be a hell of an adventure. At least I can gain some experience from it and say that I have actually changed a head gasket, lapped valves, and changed stem seals. And if it goes wrong, sell the parts.

-

Oh, dear... After reading a lot of this and seeing the pic above, I am now having to have a rethink. I am going on the expectation to be able to just get the head off, with the engine sat in the frame. I have no centre stand and it's going to be done outside. This weekend was a total no-go because we had a flooding amount of rain, so maybe next weekend. This is going to be a nightmare. And what's this 170-228 psi, I read? Mine is the triple engine, and got something like 170 | 190 | 170...

-

Thanks. I will have to clear a space somewhere out the back, maybe in the gazeebo - and keep a clean area, in case I drop a collet. Some points that I thought of are; - I need to label up every bucket and keep each shim separate, so they go back the same. I know the clearances were spot on and don't expect them to change, after a bit of cleaning and grinding. Must check clearances again, after re-assembling. - I need to find the correct bolt removal sequence, torque specs, and keep each bolt in the same order, in a template that I'll cut out of cardboard. - Make sure the head gasket fits... Do I need to drain coolant, first? I am most definitely giving it a fresh filter and oil, after all this work.

-

All points duly noted, thank you. The advice I have so far is golden. I have ordered a Holts Valve spinning tool, with two grades of compound, and a motorcycle valve spring compressor removal tool. I want to make sure I get the job right. I have a magnetic wand somewhere. If I can't find it, then I have plenty of tools to make one up. Now that I have virtually all of the tools I need, I might see how I get on, and think about starting a career in mechanics... Actually, scrap that idea. Everyone is going "electric" now, aren't they?

-

I could do with one of them. I have just read up on valve lapping and fully understand it. One thing I read up on instructed to use a suction cap, while the valve is back in the head, and turn until the compound doesn't make any grinding noise. Sounds simple enough, but the hard part will come putting the valve springs back in.

-

I didn't even think of all this! Good job I asked on here. (Best forum on the web.) Everything I ordered so far should be arriving today: Oil filter, head gasket, sump washer, already got valve seals. So, I could take the engine head off and get ready to do it, then quiz you all about this job involving valve grinding, and shims, as I'm sipping a beer, trying to figure out how to get the head off. But, wouldn't it be a shame if it decided to rain like the amazon this weekend?

-

No... This is news to me! I need to do some more homework...