-

Posts

286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Gallery

Community Map

Everything posted by leener

-

Especially if you have just ground in all the valves so it almost certainly needs re shimming now . Things might be looking up again . Where’s them feeler gauges... Oh, and six spoons of coffee, twenty sweeteners. Legs are aching from yesterday. The life of a desk job vs a mechanic.

-

Outside freezing my nuts off. Crank at T1 and arrows... going to do liquid test This is how it was set before cams off and put back at T1. Now I’m not sure what to do, other than test the rings for leakage.

-

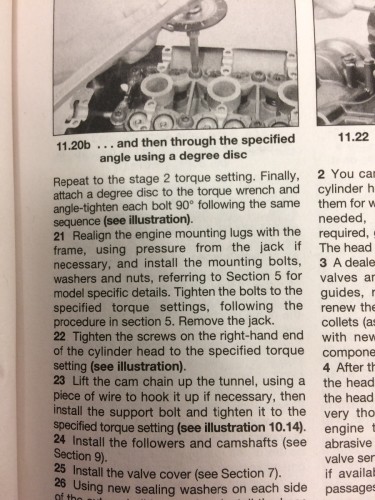

Cam cover. I reached my mental and physical capacity by the end of yesterday. I might have to take it all off, but my plan for today is to do a quick wet compression test, and then strongly consider how I set the timing, when reconstructing the head. I need to get my last phone out and examine the photos I took of the crank position, and the cams. I did it from memory, so It's entirely possible that I failed to set it up exactly as it was. This is more likely, than anything else, I think. It is also possible that there is a problem with the piston rings, but one step at a time. No work has been done on the pistons, other than carefully removing surface carbon. It's difficult to get up and start the job until the caffeine has worked its way up to the brain.

-

Ah, shhheeeeiiiiahhhttt! I did not do that. I’ll get the head back off and do the checks and make sure I have it all right. The cams were spot on, going from memory. I had the pictures of where the arrows positio and the teeth were right, but I will check and check. This is so vital, because I want to make it so I can show others how they don’t need to scrap a bike, or get into debt for repairs. I have to finish this. I might end up keeping this bike.

-

Cheers, Bob. Will try throwing liquid down tomorrow and see what happens. I did first test and hit around 50 on all three. Second test I squirted a little WD40 in each spark hole and got either 55 or 60. Tomorrow will give us a real chance to find out. I hoped that maybe the bolts were not tightened enough, thus causing air to escape. Already, the signs are bad.

-

Now I'm starting to worry. I set the crank to T1 (I think - need to see photos) at the marker, and 1 piston up, 2 down. Both arrows on the cams were facing each other....

-

I'll sort the bolts later, after I have cracked it open again tomorrow, to check the torque of the head cylinder bolts. I clearly haven't tightened them nearly enough, because the highest psi compression test was only 60. I have packed away for now, because there's only so much you can do in a day. Totally exhausted.

-

The worst problem right now is 50 odd psi on each cylinder.

-

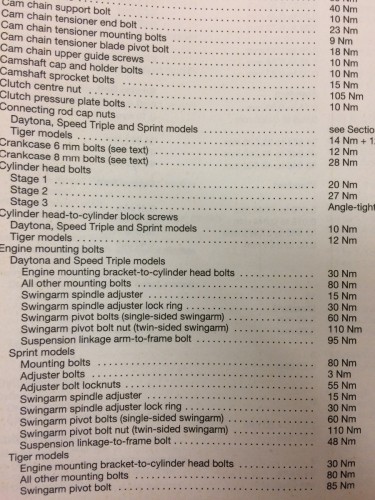

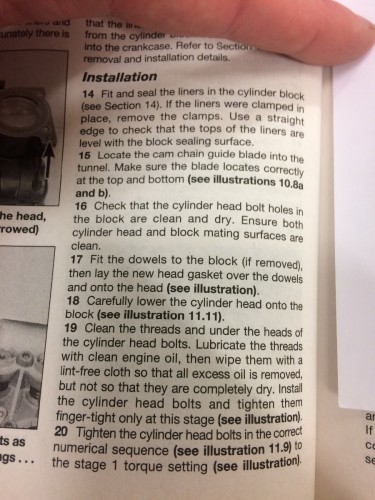

I did, and nothing leaks through at all. Perfect seal. What confused me, was the Haynes book. The torque stages were 20nm, then 27, then 90 degrees angle. I did each step, but seemed a lot less tight than when they were coming off. I noticed that the impact grade t50 torx but that I used had actually bent, from removing them. They are all in, exactly to what the manual specification states. Cam chain went up, cams lined up, chain on, ladder on, rocks cover on, with all seals in perfectly. I even cranked it by hand to ensure that the timing is correct. Then, I realised that I forgot the two bolts on the side of the head. I tried to fit them... And had some problems... One problem is that they were over 14nm going in the last CM, so very difficult, because also trying to turn the torx bit with a fat wrench is impossible. There simply isn't enough clearance. Getting then out was hard enough. Need new bolts, and a better tool. Just stopped for a sandwich, now. I'm exhausted. I've been at this thing since 9am.

-

Cheers! I certainly hope it goes well. Tomorrow is the big day. Just doing some homework before the fun begins.

-

I need to get a bit of reading done on the process for re-bolting it all together... I have one big torque wrench for over 120nm, and one little one that goes up to around 20nm, in preparation. I'm looking forward to this... And the tense moment when I go to start it. I'll take my time and check things over several times, step by step. The manual comes in handy, but I have a Haynes somewhere that I need to dig out.

-

It might be a little while before I sell it, because I am just craving to get back on. Yeah, I'll bolt it all back up next weekend, pending the weather. The cylinder bores seem OK, the pistons aren't showing any obvious issues, and I am only praying (to the big electron in the sky) that the valve stem seals are the culprit of the blue smoke starting. I will carry out a clearance check once more, just as I get the cams back on. New exhaust gaskets still need going in, and new exhaust studs are here. The head gasket will get extra special care, when going in. To me, it looked like the last one wasn't really fairing too well. The bodywork of the bike isn't great. Upon taking it apart, I have noticed a lot of paint bubbling and flaking. The rear footpeg brackets are the worst, with rusty bolts, and same for the swing arm. I may need to get that deal with. Has anyone had experience with getting the bodywork redone?

-

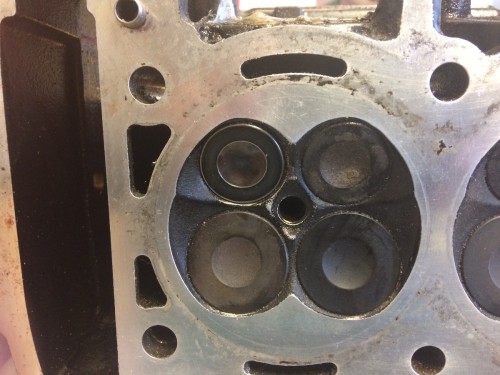

The carbon seems to be easy enough to remove from the surface, but noted the carbon burnt to the walls top. I can't see anything to tell me more about any problems, such as the piston ring. The only thing I noted was the carbon on the top of the walls, and slight scoring... I have cleaned them up as much as I have the energy to do, and will do more by the time I fit the new head gasket, and put it back together. Between us, with no prior experience, we have rebuilt the top end, which was rather fun! I managed to rip the end can off an old kawasaki micron exhaust system, that used to sound loud. I can get that to fit... Maybe later. Proud of the work we've done so far. The next part is reassembly, unless I need to do more? The rest is ready to go back on. Right now, need to do housework. Lots of it.

-

I think I’ll clean up the piston surfaces as best I can, but not keen on getting too deep into fixing it, unless I decide to buy another car and keep the bike... baby on the way, so wanted to sell the bike to afford a reasonable, cheap car, without cracking into the bank. My crappy car is due mot by 26th May, and would sooner see world peace than pass. The bores of the cylinders were scored slightly. Nothing too mad. I was pointing out that I noticed massive scoring on the wall of where one that of shim buckets sits. Just looked awful. The pic in the above post was the best pic of it. Dog was upset because I didn’t throw the ball. I’m in his garden, so I am obligated. I’ll try to snap some new pics of the cylinder bores tomorrow to show the condition... hopefully, you’ll say, “perfect! No work needed”. But I enjoy this kind of work.

-

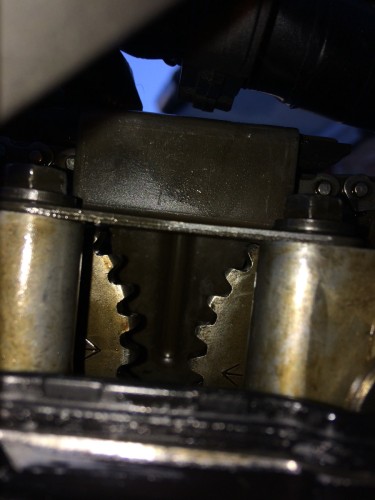

There were a few very noticeable vertical scores in 2. What really worried me, is that around the shim bucket, on the second valve for cylinder 2 has major scoring. The bucket was fine...

-

YouTube time! No idea what I’m doing, there. That is a very good prompt, indeed. I need to get a torch down the walls of the pistons to check, and try a feeler gauge down the sides. To date, I have only focused all of my attention to the valves and cylinder head. The bores in 2 and 3 could be inspected, as I left it at TDC. The cylinder walls were mildly scored. Should I drop the crank half out and get it on a bench? This is a good job to drop me in the deep end, with a huge learning curve.

-

Happy Saturday, bikers and pretend bikers. Only kidding. I know everyone in this forum is a true biker... After a hard graft of a day, me and my lady have both got all six exhaust valves done. She did two, replaces seals, lapped and seated in, even grinded off the carbon, and cleaned the ports out, on one cylinder. For someone who had no idea about engines before she met me, she’s picking it up faster than I ever did. Those collets were right gits, but I managed to get my technique by the last couple, and was getting through a lot faster than the first. I made a crude lapping tool out of a stick, mini plunger, and screw, powered by electric drill. All in all, really pleased with how it went. Tomorrow will be the intake valves, which hopefully will be much nicer to work on... beer time!

-

After a good long chat with megawatt the other night, I now have a methodical and logical process mapped out, on how I am going to get this job done. I had already assumed a few things, for example, lapping valves only taking a few minutes, when it takes time to make sure everything is sealed correctly. And, tips on techniques that I would never have thought of, without countless years of experience. I have a lot of food for thought and a lot of reassurances on things that I thought were going to be a major problem. It really helps having advice from someone with such knowledge and skill. If you ask a shop mechanic for advice, you will be very lucky to get it, and even luckier to get advice as good as what I have been given. So, big, big thanks to megawatt for once again helping me out. Your expertise is greatly valued! Bring on the weekend for some more oily fun.

-

Maybe. Best to search eBay 'sold items' to get an idea if it is worth doing, because stripping a bike down to sell is less than fun. I know because I have done it many times. It sounds like too many amps pumped through the wiring, maybe blowing several things out. Get the multimeter out and check the reg/rec, ECU, and maybe try another battery, if you have one. Check all wiring and fuses for burns, check reg/rec for resistance, (youtube), and work out how much parts are, and how long you'll spend on replacing them, vs stripping it and selling it. Many things to do. As for your brother; no idea what he did or didn't do, but that's up to you.

-

I remember when I first started riding, I took a bike into a local garage and asked him, "So, how did you repair it? And, how did you even get the tank off?". He laughed and said, "Why would I tell you this? That would be taking the bread from my family's dinner table". You may want to seriously consider speaking with megawatt. He is offering you some solid advice, with a wealth of experience, that some people would pay good money for.

-

I have send Sprint Manufacturing another email. This will be the third lot of bits I have ordered from them. Need another 8 valve seals. I also need to find suitable exhaust studs and bolts. The carbon is so thick on top of pistons 2 and 3 that it took me a long while to reduce it, even a small amount. There is still around 1mm thickness on top. I have to spend more time on it, outside. I am particularly worried about getting any material down the sides of the pistons, or in the coolant gulley. It is going to be a "approach with care" job, all the way through. I sprayed a lot of WD40 on top of the pistons during cleaning, and am definitely flushing out the oil when it is patched up. That head gasket looks to have been leaking, with earlier photos showing rust deposits around where the gasket had sat. Hopefully, none of the valves are bent. I did a valve clearance check a couple of months ago, which proved that the clearances were well in spec. I have had the bike ten months and so far; - Paid £180 for a mechanic to do an oil and filter change, and change the plugs. I didn't think I had the skill to work on the bike, at that time. - Had both tyres replaced. - Diagnosed a burnt stator and replaced it. - Replaced the fuel pump. - Checked valve clearances. - Repaired broken wiring to fuel sender. - Renewed coolant. - Oil and filter change. - New spark plugs. Now, I have done all this! I will hopefully have a chance to do the rest of the valves tonight. - All valves are coming out, being checked, scrubbed, re-seated and lapped, with new seals. One by one. And, to think - the mechanic I first visited thought that the compression ring missing from plug 1 was to blame...

-

From what I remember, 1=165, 2=190, 3=170 just before I took it apart. Something like that. But, no idea what they're supposed to be, until I can find that pesky Haynes book.

-

Cheers, mate. Tomorrow evening ok for you? Only done one valve, due to already being totally knackered. The first was only a faff because of being my first. I popped my valve cherry . I feel like a real biker, now. I'm going to buy some more stem seals. I only ordered four, just to be a cheapskate. But, if a job is worth doing, it's worth doing right.

-

I finished one valve. Re-seated, lapped with coarse and fine grit, new stem seal, and put back. Those retainer pins are a nightmare. I am too hungry and tired to continue more.

-