Admin

-

Posts

7,486 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Gallery

Community Map

Posts posted by Admin

-

-

Hello RagingCat,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

Aprilia will be offering its biggest trackday and bike demo program yet this year. (Aprilia/)It’s been a rocky year for most of us, with a lot of our favorite two-wheel events canceled out from under us and even reliably scenic go-to destinations shuttered for an indeterminate amount of time. Sure you can still go for a ride at a safe distance, but the occasional solo canyon run to that now-closed excellent mom-and-pop burger joint in the middle of nowhere just doesn’t have the same punch it used to (ask us how we know). Fortunately, there’s light at the end of the tunnel, and more than a few manufacturers have stepped in to offer up a much-needed change of scenery as well as a ride on their new models. Whether it’s a simple streetbike demo or a more involved trackday experience, these new initiatives are designed to get you on a new set of wheels and maybe boost your adrenaline back to prepandemic levels, even with public health and safety restrictions still in place. The fact that you can go out and demo a brand-new bike in 2021 is reason enough to look forward to a summer of good riding ahead.

Kawasaki’s Good Times Demo Tour is starting its 2021 schedule this month. (Kawasaki /)Among the manufacturers touting long-term rolling initiatives this year are Aprilia, Kawasaki, and KTM. Some, like Kawasaki’s Good Times Demo Tour, are often run as street rides originating at a dealer, but make stops around the country with a stable of vehicles. For 2021 Kawasaki says it’ll have a wide range of products, with bikes from the Ninja 400 to the Ninja 1000 SX, and many others in between. The Tour runs from the end of March to the end of April, mostly in the south and southeast US. Get the deets at kawasaki.com/en-us/events.

One of the models featured on KTM’s Ride Orange demo tour is the 890 Duke. (KTM/)BMW and Honda continue to offer bigger group demo rides at events like Americade and Daytona (as with the R 18 recently) or via appointments at individual dealers, but check with your local shop for availability; they can usually accommodate you. And of course, Harley-Davidson and Indian Motorcycle are constantly running demo days; the firm’s websites will list events, as will local dealers. KTM’s big ride push for 2021 is the Ride Orange Street Demo tour which features at least six track locations sprinkled into an otherwise street-biased schedule, which runs through September, ending at the Americade Rally. The models called out include the new 890 Duke, as well as popular bikes like the KTM 200 Duke, 390 Duke, and 390 Adventure. For the schedule and more info, visit: ktm.com/en-us/ktm-world/ride-orange-demo-tour.html.

Related Content: Track Days are Good for the Soul

Aprilia’s program for 2021, dubbed Aprilia Racers Days, is more racing-focused and includes dates for nine circuits across North America, where riders can sign up for a more intimate trackday experience (for a fee). They’ll get the chance to ride the latest Aprilia models, like the RS 660 and Tuono 660 models, early on, but if they’re feeling a bit more big bore, the brand-new 2021 RSV4 will come online starting April, with the Tuono V4 following shortly afterward. Each event will be supported by Aprilia trained technicians as well as partners Pirelli, Dainese, and AGV to offer expert advice, with coaching, photography, and lunch included. If you’re looking to take your race game to the next level, you can also opt for individual instruction thanks to a collaboration with Jason Pridmore’s JP43 Training. The extra-cost program is limited to a handful of riders, and only at certain Aprilia Racer Days events (Laguna Seca, VIR, The Ridge).

Whether you choose the free street ride on a brand-new model or shell out serious Benjamins for a top-notch trackday, 2021 is already looking way better than last year’s pandemic-blighted season.

-

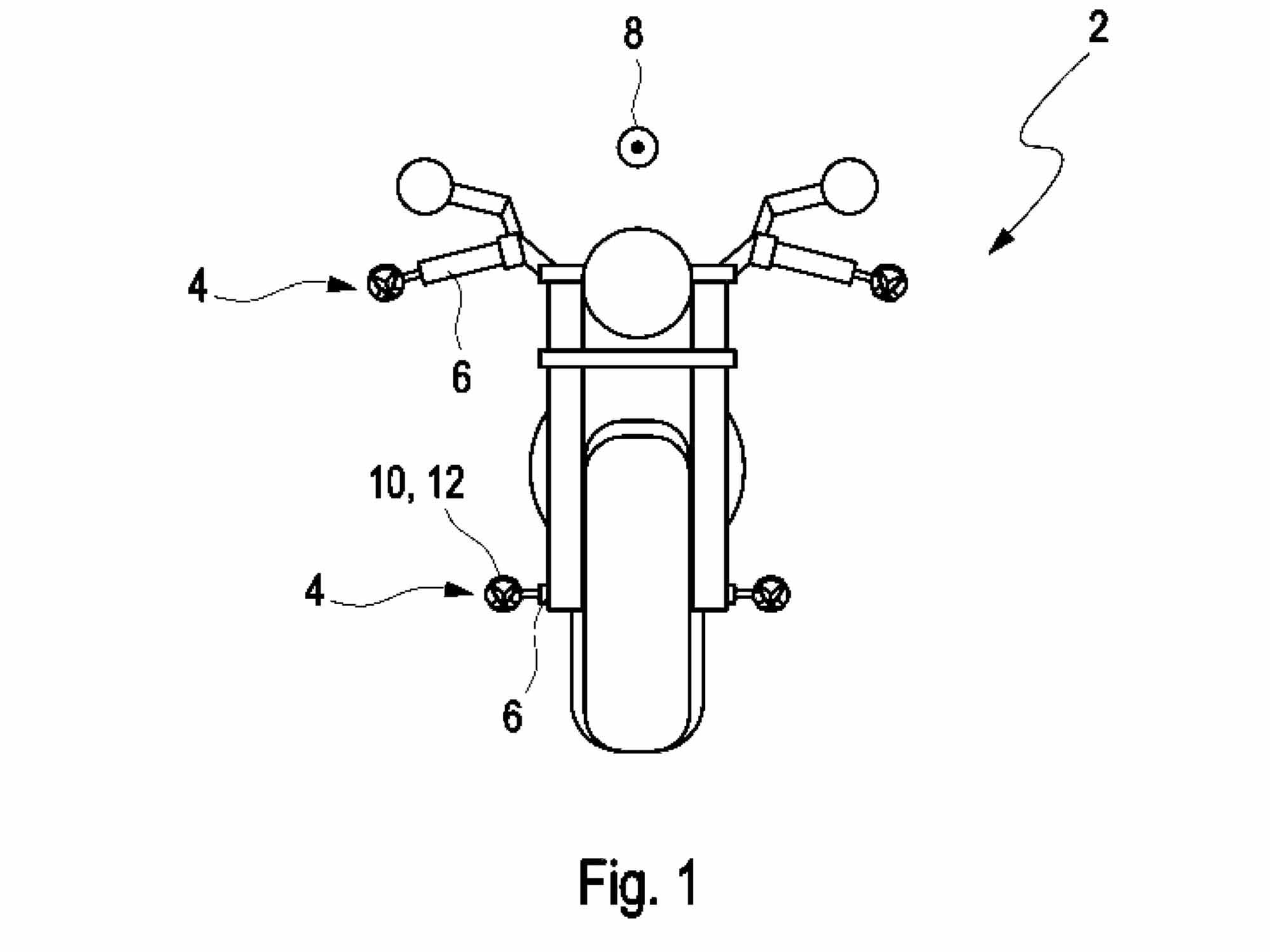

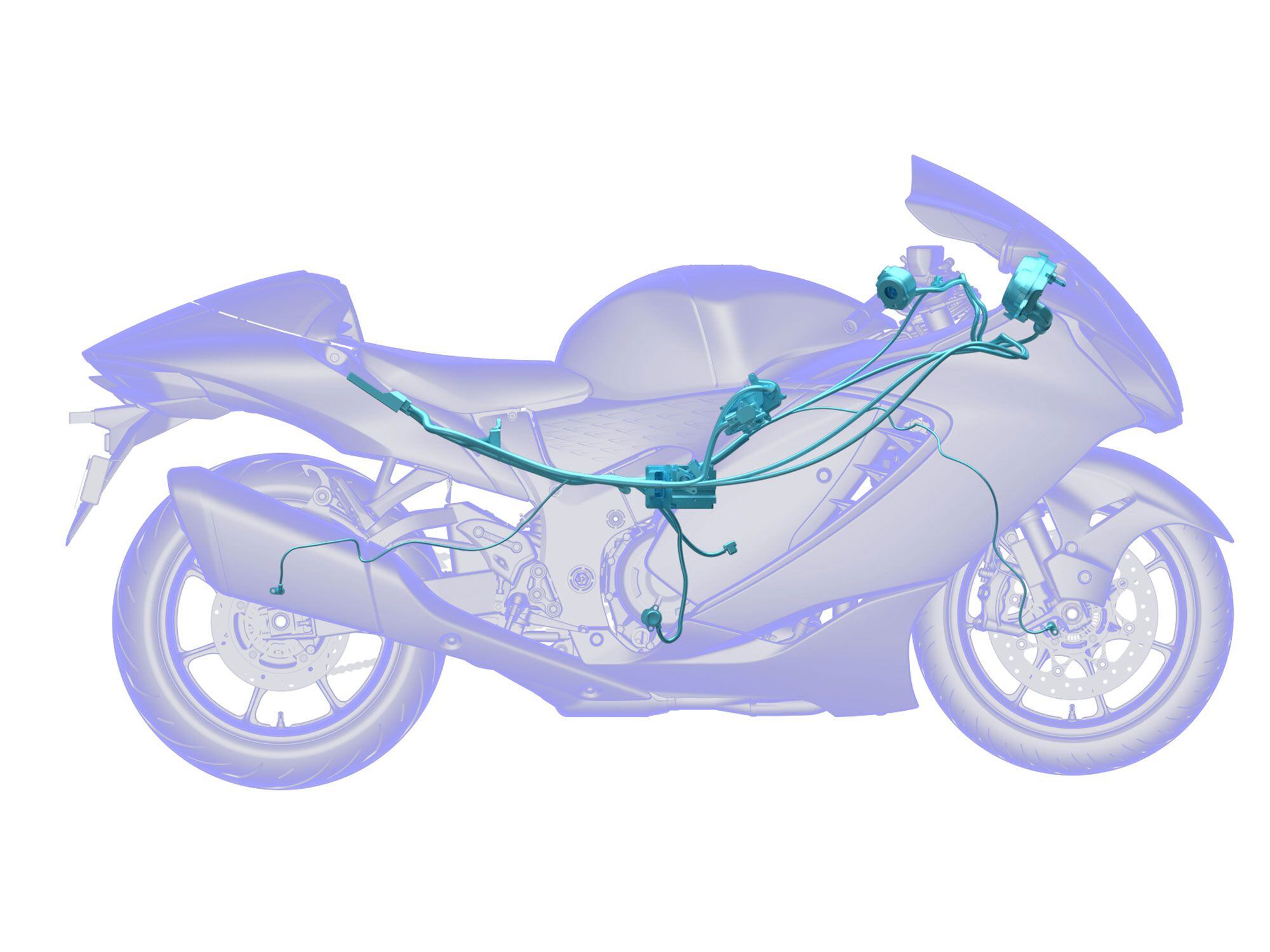

BMW’s latest safety patent uses the idea of passive radar reflectors to help bikes be better seen by a car’s radar. (BMW/)Being visible to other drivers has always been the first step toward motorcycles staying safe in traffic, but as the world’s carmakers race to develop semi-autonomous vehicles, riders are starting to face a new challenge: Being noticed by the electronic eyes of modern vehicles rather than the biological ones of their drivers.

While the vast arrays of electronic assistance systems proliferating on modern cars are made with the intention of increasing safety by reducing opportunities for driver error, motorcycles have the potential to slip through the gaps in these digital safety nets. Radar in particular is an issue. It’s fast becoming normal for modern cars to have radar systems. Front-mounted radars enable adaptive cruise control and automatic emergency braking systems by monitoring distance to vehicles ahead, while rear-mounted radars create blind spot monitoring systems. But bikes are small and often contain plastic or composite bodywork that’s relatively hard for radar to see, and that means automotive radar might not pick them up as early as it would a large, metal car. As we move toward a future where cars are increasingly semi-autonomous, with fully autonomous vehicles already under development, being seen by their radars will be as essential to safety as being seen by drivers is today.

As a maker of both high-tech cars and bikes, including the 2021 R 1250 RT that’s among the first two-wheelers with a radar safety system of its own, BMW is in a good position to understand the problem, and a newly published patent application shows that the company is already working on simple solutions to the issue. The firm has looked to the sea for inspiration—another place where radar has become ubiquitous and small fiberglass-clad vehicles share space with much larger metal ones—and borrowed the idea of passive radar reflectors.

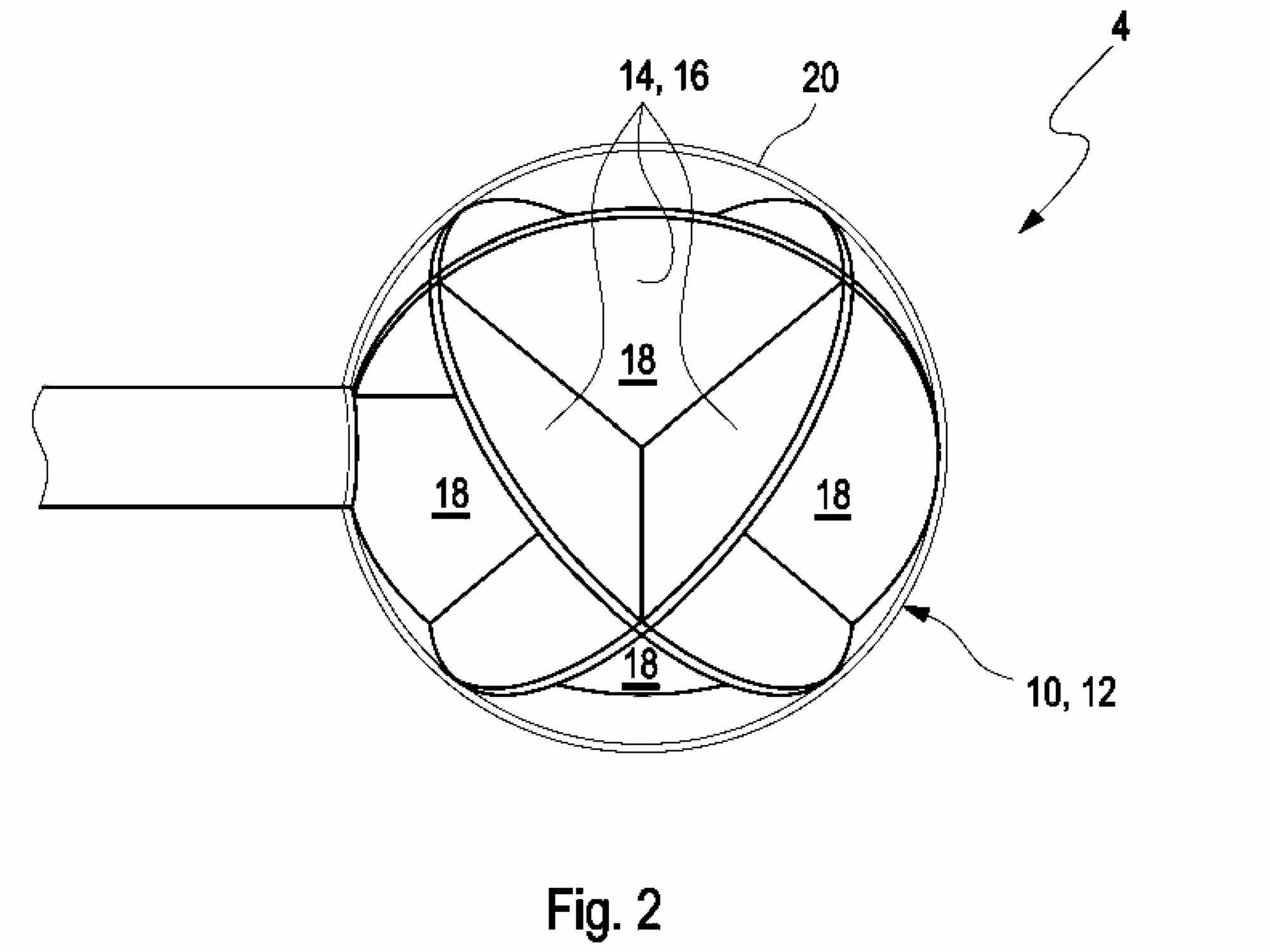

Radar reflectors are already commonplace on small boats, either in passive or active form. The passive ones are simply made of sheets of metal attached at right angles to form sets of corner reflectors that are able to bounce radar waves directly back at their source, and it’s these that BMW has adapted for use on bikes.

The small globelike reflectors would be bar-mounted to capture radar signals, and could even be retrofittable to older bikes. (BMW/)While seagoing passive radar reflectors are a foot or more in diameter, their bike-mounted equivalents can be far smaller and still reflect the millimeter wave radar used in cars. BMW’s patent application shows a bike fitted with golf ball-sized reflectors that are simply miniaturized versions of their marine equivalents. By mounting them on the ends of the bars and on the bike’s axles front and rear, there’s no angle at which a radar can be pointed at a bike without hitting at least one of the reflectors, bouncing a strong signal back to the radar sensor.

BMW’s patent suggests the reflectors could be made of plastic to keep weight down, with a metalized coating to ensure they’re still radar-reflective, and that their mounting positions mean they serve a secondary purpose as sacrificial crash protectors; if you drop the bike, they’ll be the first parts to hit the ground. This secondary purpose helps separate the BMW design from an earlier patent from Suzuki which also describes passive radar reflectors fitted to bikes.

Given that we’re all going to have to learn to share the roads with increasingly automated cars, it’s reassuring that manufacturers are considering bikes and that their solutions, while perhaps not pretty, are simple and low-cost. There’s no reason to believe that radar reflectors like these couldn’t be retrofitted to older bikes once they’re available, and even if BMW doesn’t go ahead and turn this patent application into a production system, no doubt aftermarket parts makers will soon be looking at similar ideas.

-

Hello Leanne,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

Hello David Green,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

-

Hello Algis,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

Hello dan88,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

Hello EricWo,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

Hello K1W1,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

Hello Clueless,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

-

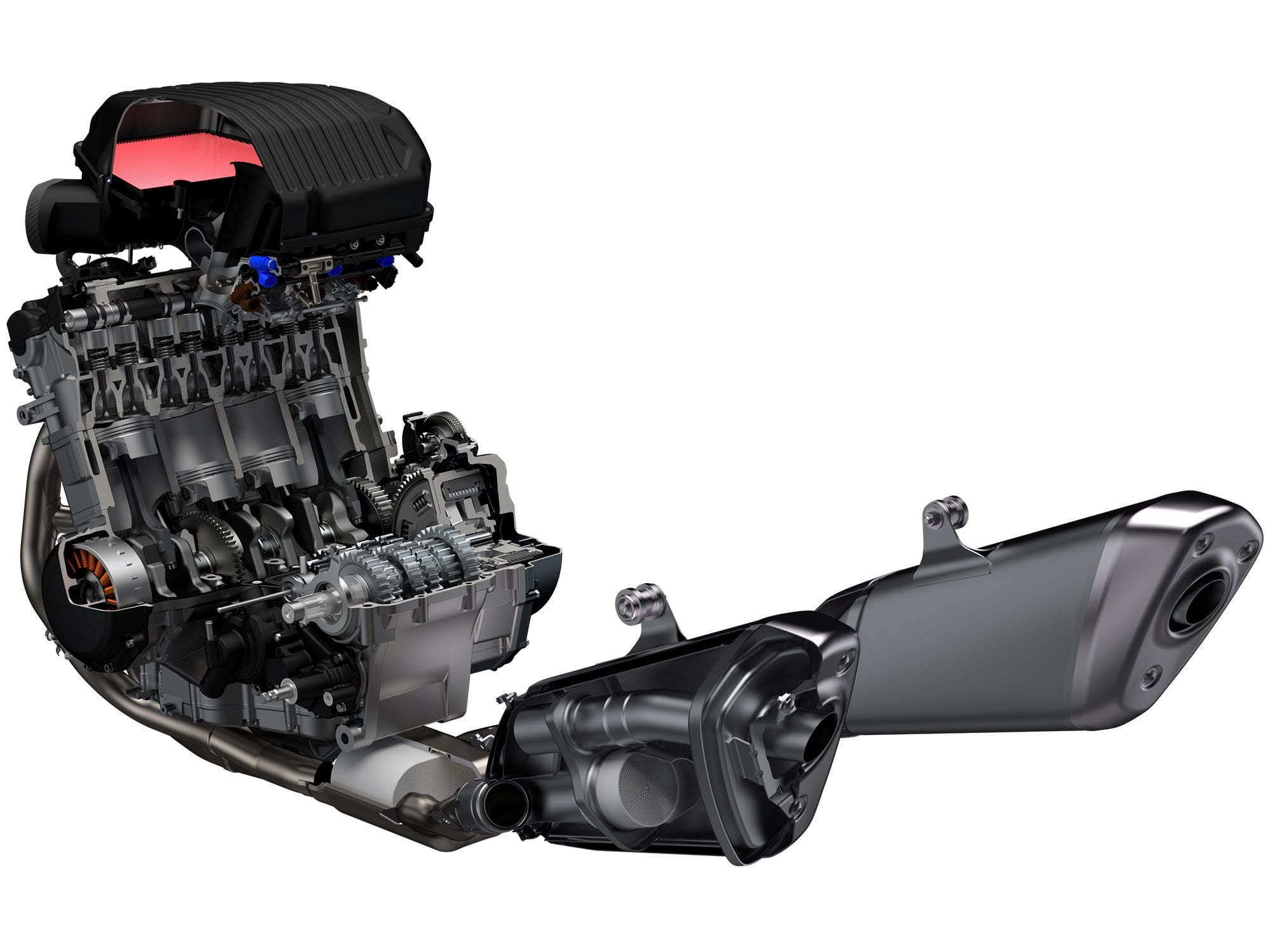

Suzuki knows the Hayabusa will see modified engines and induction systems, so has made changes to the GSX1300R’s engine to increase durability. (Suzuki/)The Suzuki Hayabusa is unusual in that so many of its users modify the engine, sometimes subjecting it to loads four or more times greater than it was designed for. Suzuki engineers are well aware of this, and furthermore, management knows it’s essential to maintain this engine’s reputation for durability. It is only when no avenues of possible improvement remain that an engine is regarded as obsolete.

In stock form, Hayabusa makes its power more through its 1,340cc displacement rather than revs. When turbocharged, it makes truly impressive power through much higher combustion gas pressures acting on its piston crowns. Fallible beings that we are, we seek ever more power, and the stress created by making that power requires periodic technical changes to handle that stress.

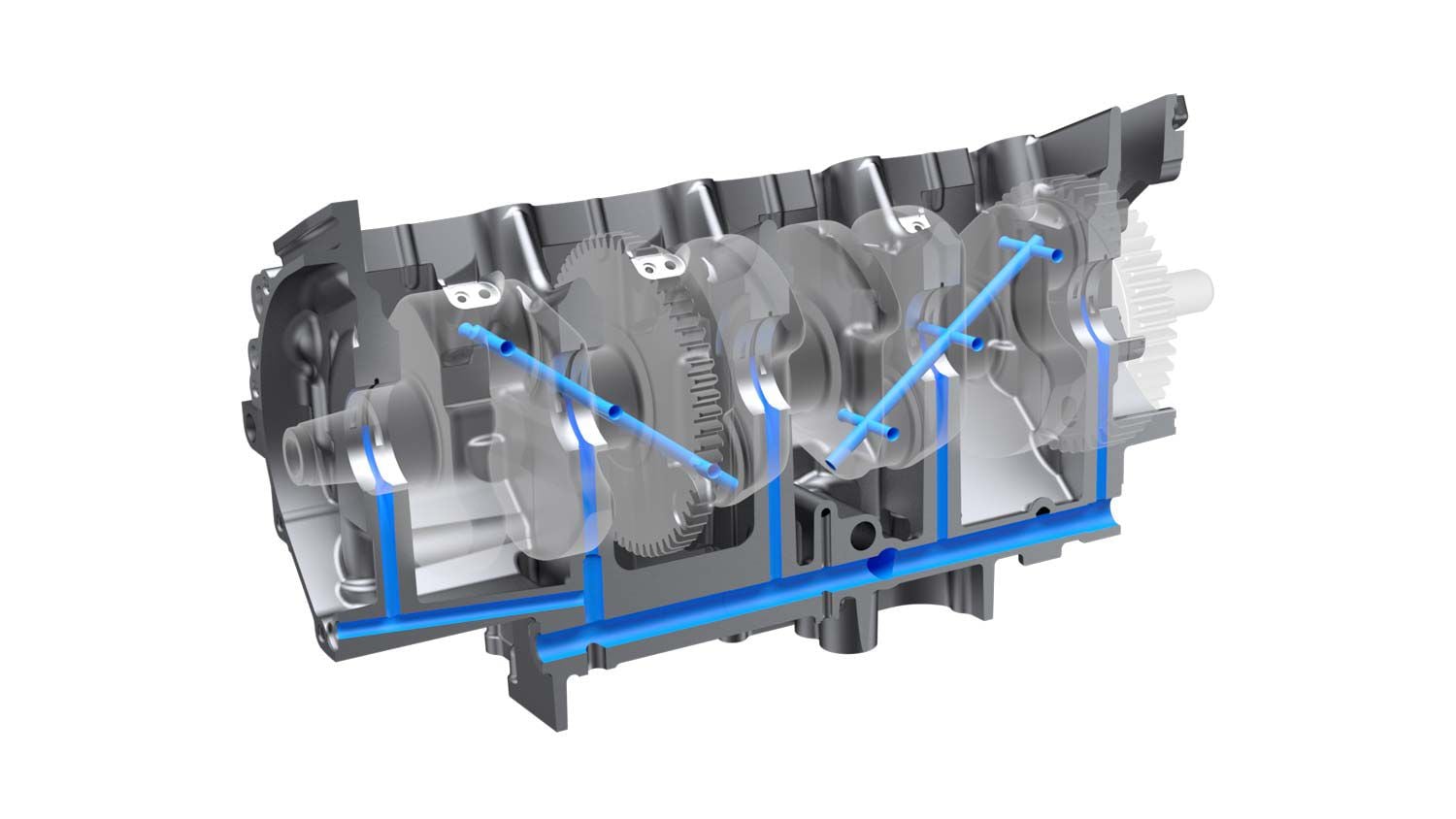

Improved Crankshaft Oiling

Engine survival depends on the oiling system. Even a momentary oil delivery shortfall or hiccup can result in a spun rod bearing, a situation in which under-lubricated bearing shells seize to the crank journal and spin in the rod or case. In the Hayabusa’s previous design, oil from the main gallery below the crank was supplied to the five main bearings; from four of those grooved and cross-drilled main bearings, oil entered drillings in the crank that conducted oil to the four adjacent crankpins. The upper main bearing shells, being less loaded, have a central groove. That, along with the cross-drilling of the main crank journals, assures there is always an open flow path from the oil pump, then into that groove, into the main journal, and ultimately by interior drillings to each crankpin and con-rod big-end bearing.

The 2022 Hayabusa features new oil passages for better oil supply and durability. (Suzuki/)In the new design, a pair of diagonal internal drillings join the numbers 1-and-2 and 3-and-4 crankpins, passing through the main journal between them, where they pick up oil. From the graphics supplied by Suzuki, it appears that all crankpins are now also cross-drilled. Suzuki tells us that these changes have increased crank-bearing oil flow by more than 50 percent—without any change to the oil pump.

The Oil Pump’s Job Is to Replace Oil Lost From Bearings

Loads on crank bearings are not supported by pressure from the oil pump—it just pushes oil into the unloaded side of each bearing, while the very high pressure that supports the loads is generated by the viscosity of the oil, being swept constantly into the loaded zone by crank rotation. Loaded-zone pressure in supercharged engines can exceed 10,000 psi—more than 150 times stock pump pressure. The aim of cross-drilling is to ensure that the low-pressure side of every bearing is constantly able to receive “refill oil” from the pump. Bearing loads squeeze oil out the sides of the bearing, and the pump’s job is to continuously replace it. These changes have made that job easier.

Reducing Crankcase Distortion During Assembly

In an engine as heavily stressed as those in many modified Hayabusas, it is essential that the tightening of the bolts holding the cases together be uniform so distortion doesn’t occur. Crankcase distortion can result in unequal or edge loading of bearings. To achieve uniformity of bolt tension, Suzuki has switched from torque-based bolt tightening to angle-based. Torque-based tightening can work well if friction is identical from one bolt to the next, but angle-based tightening eliminates friction as a possible source of variation in bolt tension. The bolts are run in until they make solid contact, then are tightened by rotating each one through a specified angle. It’s spooky but reassuring to watch this on an automated production line.

Roll-formed Internal Threads in the Crankcase

Another durability improvement is a switch from internal case threads, which are cut with a tap, to cold-forging them by internal thread rolling. The advantages of roll-formed threads are that the material is work-hardened by cold-forming and the thread surface material is placed in compression by the high-pressure rolls. Cracking under stress requires tension, so putting residual compression into the threads means that applied load must first overcome that compression to even begin to create tension. The result is threads with a greater margin against failure. In one study I found, switching from cut to rolled threads increased strength 23 percent.

Improved Pistons and Con-rods

Today’s short “ashtray” pistons have a very short heat path from the hot piston crown to the wrist pin bosses. Raising boss temperature, plus very heavy loading, can lead to lube failure and scoring or the pickup of aluminum piston material on the wrist pin. This would be especially likely under the much higher pressures of turbocharged combustion. In fact, this happened when Ducati’s 916 went racing, and also in some modified BMW S 1000 RR applications. Part of the solution is the piston-cooling oil jets found in modern engines, but there is also another way. That is to maximize the area of wrist pin support in the rod and piston to more easily carry combustion loads, while sacrificing some bearing area in the opposite direction.

A cross section on the 2022 Hayabusa’s piston. (Suzuki/)Tapering the sides of the small-end bearing in the rod (narrower at the top) places maximum width at the bottom to bear combustion loads, and tapering to a narrower width at the top where the only stress is that required to pull the piston downward on its intake strokes. The inner faces of the piston’s wrist pin bosses are similarly angled to maximize boss width at the top, where the piston bears hard against the top of the wrist pin. Such tapered-top rod small ends have been used in many designs to gain bearing area to reliably carry high combustion pressures. Supercharged aircraft piston engines were a prime example.

Incidental reductions in piston and con-rod weight were also achieved—26 grams per piston and 3 grams per con-rod. The wrist pin has also been made shorter.

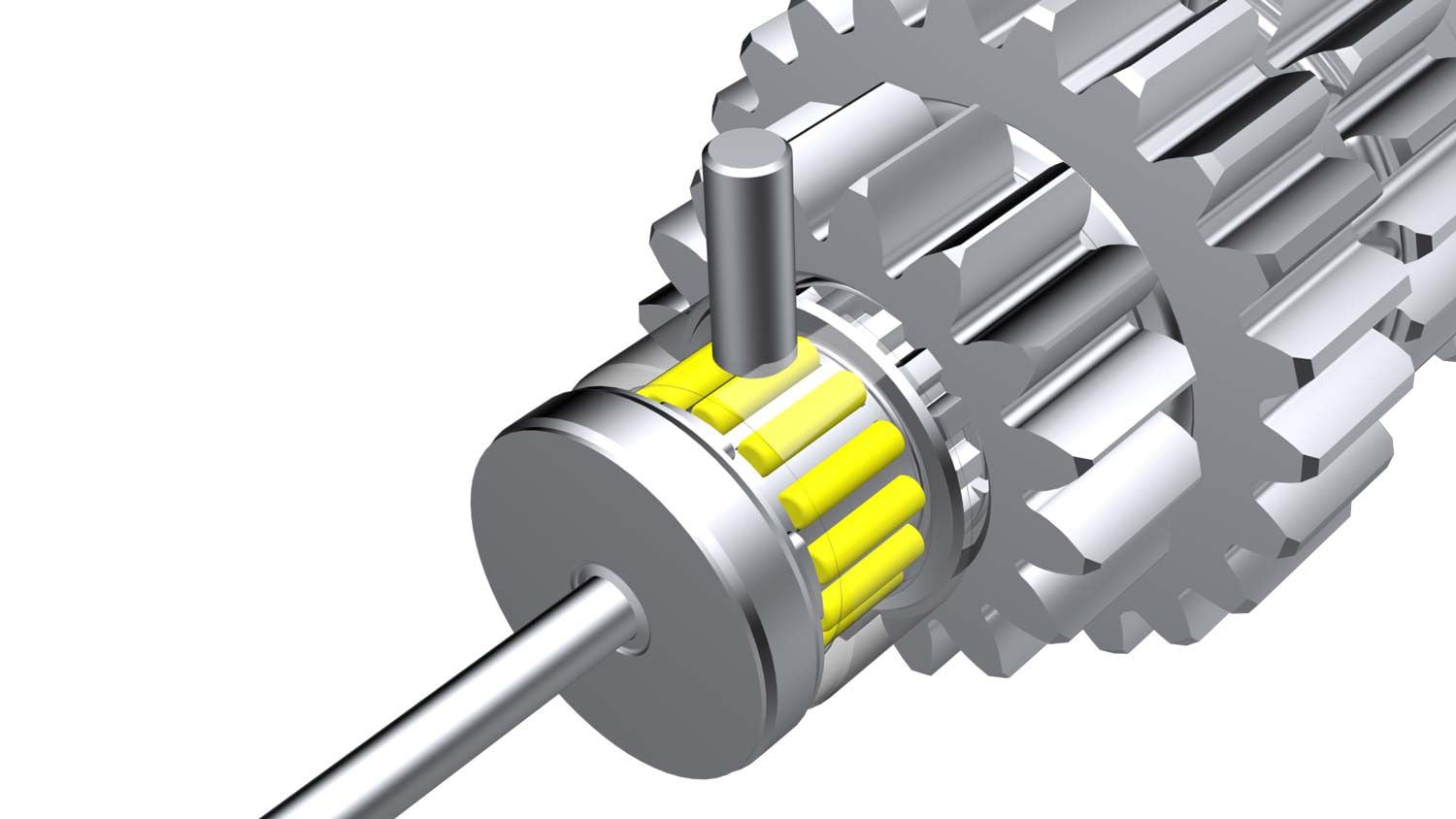

Gearbox and Shifting Changes

Gearbox shafts are typically supported at one end by a ball bearing, which positively locates the shaft endwise. The other end is then supported by a needle roller, which is able to accommodate the difference in thermal expansion between the steel shafts and aluminum case. The length of those rollers has now been increased by 18 percent. Suzuki tells us that in adopting a quickshifter, some detailed gearbox changes were required; these longer needle rollers plus changes to the gear selection mechanism.

A new gearbox needle roller bearing featuring new longer rollers. (Suzuki/)There is also an improved slipper-assist clutch, and updates have been made to shifting to work with a bidirectional quickshifter. Plate-to-plate pressure and clutch slip torque are through ramps increased by engine torque, making some reduction in clutch lever pull force possible (no more “Oh my aching wrist tendons!”), and when the torque goes the other way (rear wheel driving the engine on closed throttle) back-torque acting through those ramps reduces plate-to-plate friction, allowing slippage during braking to prevent the upset of dragging or hopping of the rear wheel.

Related Content: 2022 Suzuki Hayabusa Tech Explained

Stiffer Valve Springs and Wider Cam Lobes

As part of reducing emissions, valve overlap and duration (the number of crank degrees during which the valve is off its seat) have been slightly reduced. By requiring the same valve motions to be performed in slightly less time, this increases the accelerations required from both cam and spring to make the valve and tappet follow the cam contour. To prevent possible valve float, a phenomenon in which the valve train fails to follow the cam contour and instead rises or “floats” off of it, stiffer valve springs have been provided. To enable the oil film between cam lobes and their tappets to carry these increased acceleration and spring loads, the lobes have been made a bit wider; the heavier the surfer, the bigger the board.

Stiffer valve springs combat valve float as valve opening duration decreases in the 2022 Hayabusa. (Suzuki/)Because the Hayabusa engine is an older design and is not under pressure to run at ever-higher revs, as sportbike powerplants did in their day, it continues to use the classic inverted-bucket valve tappets rather than the lighter finger followers found in the most recent engines. Indeed, the Hayabusa is remarkable for its low peak-power rpm of 9,700. That rpm, with the 65mm stroke, gives a moderate peak piston acceleration of 4,300g. Compare this with 600 Supersport numbers as high as 7,000g, and the 10,000g of the 20,000-rpm era in F1.

Improved Cooling

Just as it’s possible to space an air-cooled engine’s cooling fins so close together that cooling becomes worse rather than better, so it is with radiators. Suzuki has increased the throughput of cooling air past Hayabusa’s radiator by about 8 percent.

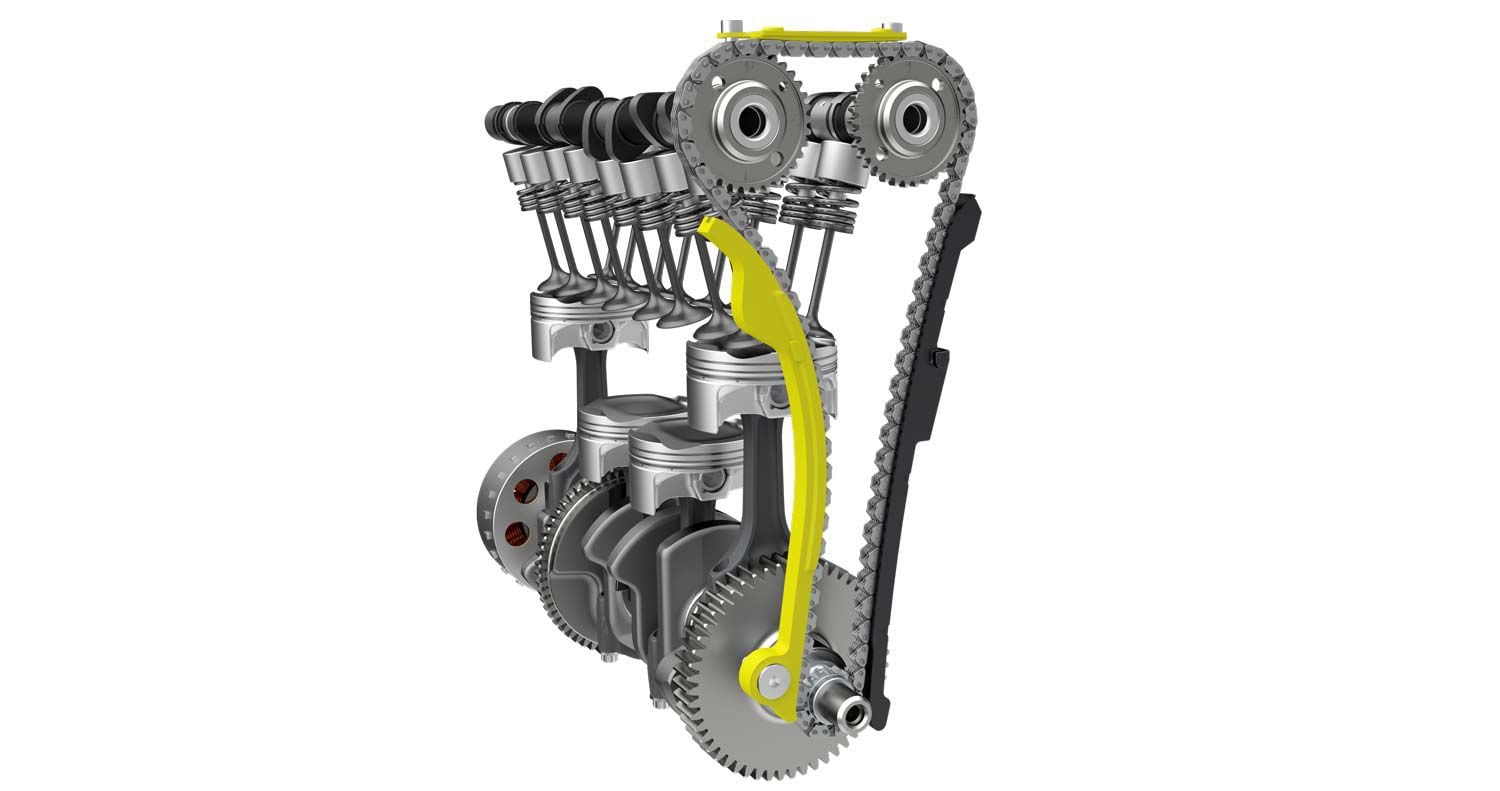

The cam-chain tensioner has been redesigned to minimize chain runout and is slipperier. (Suzuki/)Improved Cam Drive

Engineers are delighted when cam drives function reliably, because they know that all kinds of unwanted oscillations and parts damage can result when things are a little off. Why? Because the crankshaft doesn’t rotate smoothly, but rather in a series of speed variations as each cylinder fires. And because the cams’ resistance to rotation takes the form of sudden resistance, as valves are accelerated up off their seats, and sudden speed-up as fast-closing valves decelerate to seat at a survivably low speed (valves do not snap shut—that would quickly break them). Connecting two such “lumpy” processes together with a chain requires creative cut-and-try. In this case, Suzuki has redesigned the cam-chain tensioner “to minimize chain runout” and have added a slippery “Teflon veneer on the slipper surface” to reduce friction. Keeping up, not with the Joneses, but with the stress produced by hard-riding owners.

Reading about all this improvement, I’d like to have my own design updated.

-

Hello Rubberdown93,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

QJMotor bikes largely share Benelli platforms, and the forthcoming adventure model will likely share some styling cues with the current 750cc adventure bike. (QJMotor/)It’s only been a year since Benelli’s parent company Qianjiang created its “QJMotor” brand, but it has already built an impressive model range across a variety of styles and capacities, from 125cc to 800cc, and these leaked images show there are even more bikes on the way.

At the moment QJMotor’s international plans are unclear. The firm is establishing itself as a high-end leader in China, aiming to break preconceptions of poor quality and low specifications by relying heavily on European components including Brembo brakes and Marzocchi suspension. Its bikes largely share Benelli platforms, which means they’re designed to meet international regulations, so there appears to be little standing in the way of the firm as far as when it decides to start selling models outside the Chinese market.

Leaked images show the new lightweight adventure model as having a four-cylinder engine based on the Benelli TNT 600. (QJMotor/)The first of the new models to be leaked is this 600cc four-cylinder adventure bike developed around the engine and frame of the Benelli TNT 600. The same underpinnings were also used for QJMotor’s first model, the SRK 600, which went on sale last year featuring styling and suspension specs that put the Benelli-branded version to shame.

RELATED: Benelli 600RR Leaked

The new adventure model shares its styling cues with the firm’s SRB 750 parallel-twin adventure bike, itself set to be the basis of Benelli’s yet-to-be-launched TRK 800. As such it’s easy to see that even if QJMotor’s own offering doesn’t make it to international markets, a Benelli-branded reworking of the bike is a likely proposition. Tech-wise, official type approval information for the as-yet-unreleased model shows that it weighs 233 kilograms (514 pounds) fully fueled, with 80 hp on tap from the familiar Benelli-based four-cylinder engine. As with other bikes from the same company, it appears to use Brembo brakes and the ABS is Bosch’s 9.1MB system.

The other new image shows a naked SRK700, which uses a 693cc parallel-twin motor. (QJMotor/)The second new QJMotor model to leak is this, the SRK 700, and while it shares the “SRK” title and similar naked bike styling to the SRK 600 that’s already offered by the firm, it’s a very different machine under the skin. Where the SRK 600 uses the Benelli-developed four-cylinder engine from the TNT 600, the 700 uses a parallel-twin, 693cc motor. In its overall design layout and that 693cc capacity it’s a close match to the twin featured in CFMoto’s new 700CL-X, but the bike’s type approval documents list it as being an in-house-manufactured engine called the QJ283MU.

The decision to create a new 693cc engine, with a 75 hp peak power, is doubly strange because the firm already has a 753cc, 80 hp parallel twin of a completely different design from the Benelli Leoncino 800 at its disposal. With a 192-kilogram (423 pounds) wet weight, the SRK700 looks to be a pretty close match, spec-wise, to bikes like Yamaha’s MT-07, and with the addition of a Chinese-style price tag could prove tempting, particularly since it appears to be fitted with Brembo brakes and Marzocchi suspension.

-

The 2021 BMW R 1250 RT gets a ton of tech in a comfortable and capable chassis. (Simon Palfrader/)When it appeared in 1976, the BMW R100RT model was the relaxed sister of the elegant and much sleeker R100RS. The R100RT was a fully dressed touring bike and featured a protective fairing derived from that of the R100RS, built fatter and fitted with a large straight-up windshield. The R100RS faded away by 1984, but the R100RT held on, as it was highly functional and fulfilled the needs of a good percentage of motorcyclists.

When the new 1996 R1100 boxer twin replaced the last of the classics, the /7, the R1100RT was the flagship of the R1100 models range. It offered the same comfort and weather protection that made the original R100RT a success, but with a much more aerodynamic shape that bridged the designs of the previous RT and the R100RS. The RT model evolved steadily from there until the latest GS models took over the role of company flagship, but its unmatched efficiency and wonderful road manners meant it never faded into the background.

For 2021 BMW upgraded the electronics on the BMW R 1250 RT adding lean-sensitive ABS and traction control. (Simon Palfrader/)The 2018 adoption of the 136 hp, 1,250cc, DOHC, four-valve boxer gave new credibility to the RT’s performance potential. Now BMW Motorrad has further enhanced the model’s appeal, offering an attractive 2021 edition with state-of-the-art technological advances. The new R 1250 RT is an absolute technological wonder, perhaps the most advanced motorcycle in the touring domain, and most importantly, it’s extremely easy to use.

The R 1250 RT is equipped with two electronics suites, one to manage the bike’s dynamic functions and one managing the sophisticated engine. The two are fully interconnected, but I still rate them as two separate units given the multitude of functions they perform, both independently and cooperatively. The dynamic function suite is based on the latest Bosch six-axis inertial platform, the most advanced unit available, dedicated to ensuring safety and comfort levels never before offered.

More advanced electronics just adds to the rider’s confidence in the R 1250 RT’s abilities. (Simon Palfrader/)The evolution of the antilock brakes provides a good example. With the new Full Integral ABS Pro system, the rider can activate the entire braking system with either the right-hand lever or the pedal. Both dual 320mm front rotors and their Hayes four-piston calipers and the rear 276mm rotor and two-piston floating caliper apply braking force from rider input, but also take into account the lean angle of the bike (cornering ABS) to automatically calibrate the amount of decelerative force applied to each wheel, calculating weight transfer in consequence of the braking force applied. This global ability to modulate the brakes frees the rider from the additional stress of worrying about lock-up or running wide.

The renewed Dynamic Traction Control is further improved to ensure maximum control under all riding conditions. Dynamic Traction Control includes hill start control and can be integrated with the addition of the optional Riding Modes Pro, which offers four riding modes including Dynamic mode for a more spirited riding style and engine drag torque control under deceleration. There is also Eco mode, conceived to optimize fuel consumption when riding on open roads or highways.

A front-facing radar allows for active cruise control, which keeps a set distance from the vehicle in front. (Simon Palfrader/)The new Dynamic Cruise Control is standard equipment and acts not only on the throttle but also on the braking system in order to ensure that a selected speed will not be exceeded going downhill. Active Cruise Control, available as an option, offers the ability to modulate the R 1250 RT’s speed in relation to that of the preceding vehicle to maintain a constant following distance as selected by the rider. This is achieved by a forward-looking radar that talks to the engine ECU. A set of dedicated cruise-control switches is located on the left grip, and an icon indicating the precise following distance appears on the bike’s 10.25-inch TFT display. This screen also gives access to the connectivity apps, the navigation system, various assistance and safety apps, and bike management electronics.

The new TFT display ensures perfect readability in all lighting conditions and integrates navigation as well as smartphone connectivity, allowing the phone to be stored in a separate compartment where its battery can be recharged by an inductive system or by a USB connection. The massive electronics suite includes an optional audio system and adaptive LED headlights.

The R 1250 RT’s 10.25-inch TFT display is bright and easy to read. (Simon Palfrader/)The latest edition of BMW’s boxer twin has achieved Euro 5 homologation thanks to a highly advanced ECU allowing the motor to maintain the previous model’s 136 hp at 7,750 rpm and 105 pound-feet of peak torque at 6,250 rpm while still reducing emissions. That torque number is impressive, approaching the 100 pound-feet per liter mark, and the torque curve as a whole is generous from 2,000 rpm on, with 88.5 pound-feet available at just 3,500 rpm.

This motor retains the same bore and stroke measurements of its forbear, 102.5mm and 76mm respectively, and runs at a 12.5:1 compression ratio. The combustion chamber features an extremely compact profile with valves set at 18-degree included angle, 8 degrees for the intake valves, and 10 degrees for the exhaust. Valve diameters are 40mm for the intake and 34mm for the exhaust. Each cylinder breathes through 52mm throttle bodies equipped with twin injectors.

The BMW technical team continues to evolve their legendary boxer twin to meet modern levels of sophistication. A variable timing and lift valve train modulates these two fundamental factors to adjust the engine response in relation to the demand of power and torque. Meanwhile, combustion is rigorously optimized to control emissions under all riding conditions. This highly complex process features the mechanical ability to shift from moderate to high-lift cam lobes and to reconfigure the camshafts in order to vary cam overlap. The valve train operates via finger-type cam followers. In addition, the inlet valves follow asynchronous opening timings in order to induce a high swirl turbulence and induce optimal combustion of the intake charge.

A flat torque curve lets the R 1250 RT come out of corners with ease. (Simon Palfrader/)The combination of clean emissions and abundant power characteristics starts with the valve train, but an advanced sequential injection system and a large-capacity catalytic converter finish the job. The fundamental digital management functions are performed by a BMS-O ECU. The final touch of efficiency comes via the air/liquid-cooling system, which concentrates cooling fluid in the cylinder heads and the upper sections of the cylinders, where it brings the most benefits.

The chassis structure centers on the massive engine block, which is employed as a stressed member with bolted frame elements front and rear. The fully adjustable ESA suspension units use a front Telelever and rear paralever unit, with fully electronically managed Dynamic ESA “Next Generation” available as option. The chassis spans a relatively short 58.5-inch wheelbase. Steering geometry is set at 25.9 degrees of rake (though with the Telelever suspension that varies with the wheel travel) and 4.6 inches of trail. The R 1250 RT rolls on 120/70-17 front and 180/55-17 rear radials, and the standard seat is set at 32.5 inches above the ground, though its position can be lowered to 31.7 inches. BMW claims a curb weight of 615 pounds, but weight distribution front to rear has not been disclosed.

The profile of the new R 1250 RT is elegant, almost sleek, particularly in the brilliant metallic blue Sport version, but the front view shows a massive frontal area. This is fairly logical, given the bike’s mission of delivering maximum high-speed comfort in any weather. Wind tunnel research was used to develop airflow that diverts turbulence away from the rider, and the windshield is adjustable to prevent buffeting on the rider’s shoulders and helmet. On the highway section of our test, the R 1250 RT delivered incredible and almost total aerodynamic comfort at 100 mph on the Italian autobahn. In case of riding in low temperatures, heated grips and seats can be employed.

In the raised position, the BMW R 1250 RT’s windshield cleanly diverts wind over the rider’s head and shoulders. (Simon Palfrader/)The engine is simply superb, with instant meaty throttle response at any speed, with supreme engine torque delivery assisting magnificently in both city and backroad duty. A balance shaft kills all vibrations coming from the boxer twin’s offset cylinders. Speaking of throttle response, I started the ride in Road mode which makes the throttle less direct and not as impressive. But switch to Dynamic mode and the engine’s response is connected and direct—as if the engine is connected to your wrist. Spot-on. Period.

On smooth and flowing roads, the 2021 BMW R 1250 RT is a dream. (Simon Palfrader/)The steering is firm, precise, and stable even past the 120 mph mark on smoother and flowing roads. Off the highway, the R 1250 RT remained smooth and agile in medium to fast sweepers, with a front wheel that feels light but solidly in contact with the ground, allowing easy and instinctive control. On narrow and twisting Apennines mountain roads, badly deformed by roots growing underneath the surface of the road, the R 1250 RT was not as impressive, feeling top-heavy and less composed, with a bit of unpredictability.

The optional adaptive LED headlights work terrifically on dark twisting roads. (Simon Palfrader/)The R 1250 RT offers extra security at night with a powerful LED headlight system, even in standard, nonadaptive trim. But upgrade to the adaptive headlight system and it’s simply terrific with the ability to project a powerful volume of light on the inside of a curve without disturbing the drivers of oncoming vehicles.

The 2021 BMW R 1250 RT has been painstakingly conceived, designed, and honed to offer a satisfying ride on almost any road. Its engine is a superb piece of engineering that connects a pleasing traditional design with contemporary technology. And does it all with supreme class and composure. A proper continuation of the RT’s touring excellence.

2021 BMW R 1250 RT Specifications

MSRP: $20,190 Engine: 1,254cc, DOHC, air/liquid-cooled flat twin w/ BMW ShiftCam Bore x Stroke: 102.5 x 76.0mm Transmission/Final Drive: 6-speed/shaft Claimed Horsepower: 136 hp @ 7,750 rpm Claimed Torque: 105 lb.-ft. @ 6,250 rpm Fuel System: EFI w/ ride-by-wire Clutch: Wet, multiplate; hydraulic actuation Frame: Two-section w/ load-bearing engine Front Suspension: 37mm BMW Telelever, central spring strut; 4.7 in. travel Rear Suspension: BMW paralever, WAD strut, spring preload, rebound damping adjustable; 5.4 in. travel Front Brakes: 4-piston fixed calipers, 320mm floating discs w/ BMW Motorrad Integral ABS Rear Brake: 2-piston floating caliper, 276mm disc w/ BMW Motorrad Integral ABS Wheels, Front/Rear: Cast aluminum; 17 x 3.50 in. / 17 x 5.50 in. Tires, Front/Rear: 120/70ZR-17 / 180/55ZR-17 Rake/Trail: 25.9°/4.6 in. Wheelbase: 58.5 in. Seat Height: 31.7/32.5 in. Fuel Capacity: 6.6 gal. Claimed Curb Weight: 615 lb. Contact: bmwmotorcycles.com -

Hello Bobby,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

-

-

Benelli is giving its TNT 600 a restyle and upgrading performance as well. (Benelli/)When the Benelli brand was revived by Andrea Merloni back in the late ’90s, it hoped to become a genuine rival to the likes of Ducati and Aprilia as an Italian superbike maker. That didn’t come to pass, but after years of stagnation following its sale to Chinese brand Qianjiang in 2005, Benelli is having something of a resurgence with an increasingly convincing model range and fast-growing sales in its Italian home market.

Now one of the company’s key models, the TNT 600, is getting ready for a revamp that should bring it back onto the European market years after it was forced off sale by emissions limits, as well as adding a useful performance and handling boost.

The cancellation of last year’s EICMA show in Milan meant the usual platform for Benelli’s new releases was eliminated, and as a result we’ve yet to see any significant updates to the company’s range for 2021, but this revamped TNT 600 has emerged via Chinese type approval documents. In addition to a handful of technical details, the documents helpfully include a photo that gives a glimpse of the bike’s updated styling.

Compare it to the current US-version of the TNT 600. (Benelli USA/)Visually, the updates are more extensive than they first appear. The headlight unit is the same one that was introduced with a minor revamp shown in 2019, packing LED bulbs instead of halogen ones and topped with a TFT color dashboard. However, the side panels are redesigned, with a slimmer look than the old ones and a pointier front edge on either side of the fork. Above them, the tank is the same as before, but the seat unit is completely new, with scooped-out moldings on each side that appear to funnel air to the underseat exhaust. That exhaust also appears to be updated with a more oval shape to the twin mufflers under the pillion pad.

RELATED: Benelli 600RR Leaked

Mechanically, the most obvious update is a new swingarm. It’s actually the same part that’s used on the new, Chinese-market QJMotor SRK 600—the first model to come from a new brand created by Benelli’s parent company, Qianjiang. It’s a shame that the rest of the SRK’s styling hasn’t been carried over as well, since the QJMotor is a sleeker-looking bike, but the updated Benelli also gets the same higher-spec fork used on the SRK 600, along with the genuine Brembo calipers and Bosch ABS. Performance-wise, the bike is understood to use the same 80 hp engine as the SRK 600, which is a substantial hike compared to the 67.1 hp claimed for the current US-market version of the TNT 600. While we still don’t know when the updated TNT 600 will be revealed, its appearance in type approval documents suggests it can’t be far from production now.

-

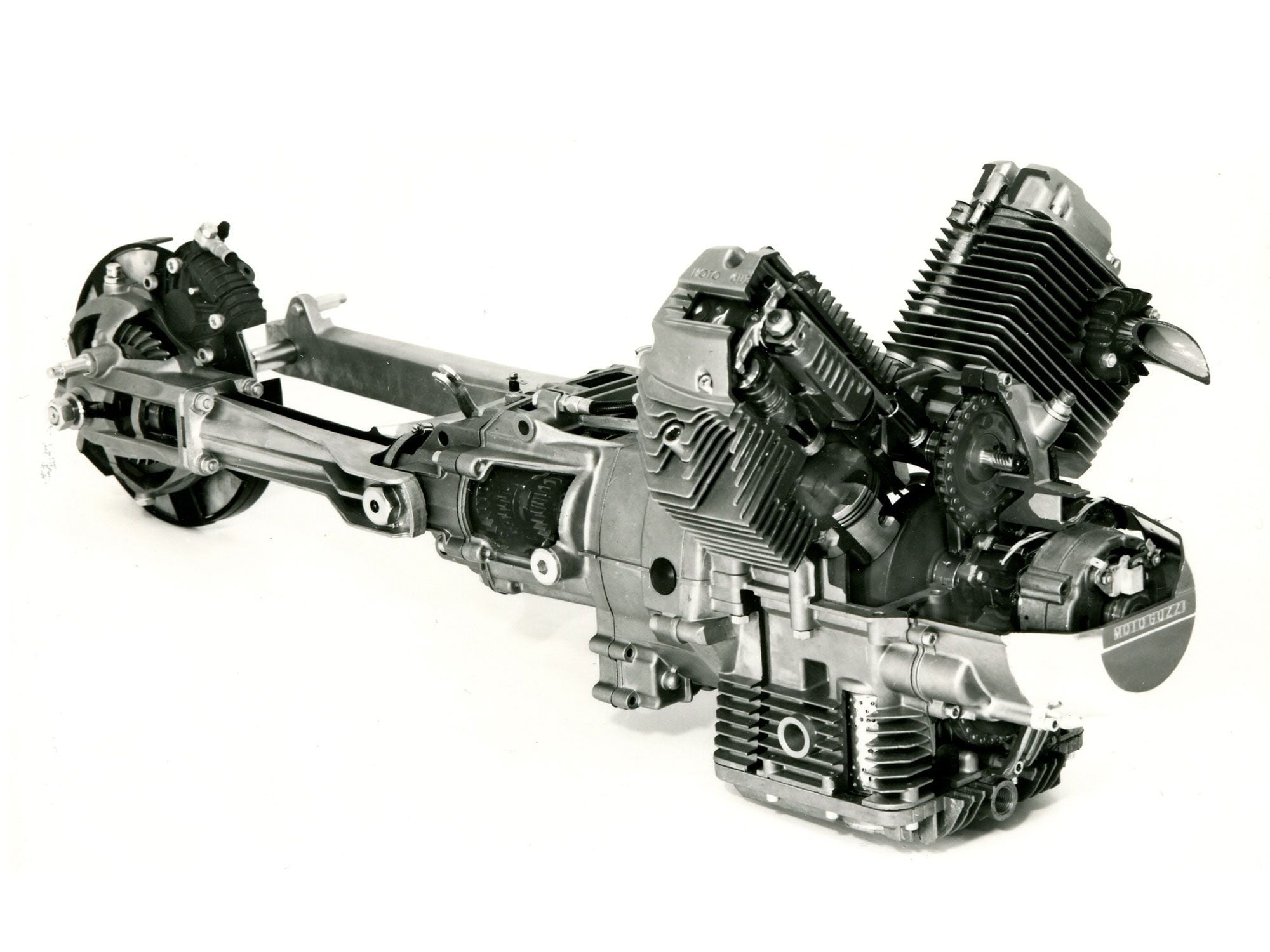

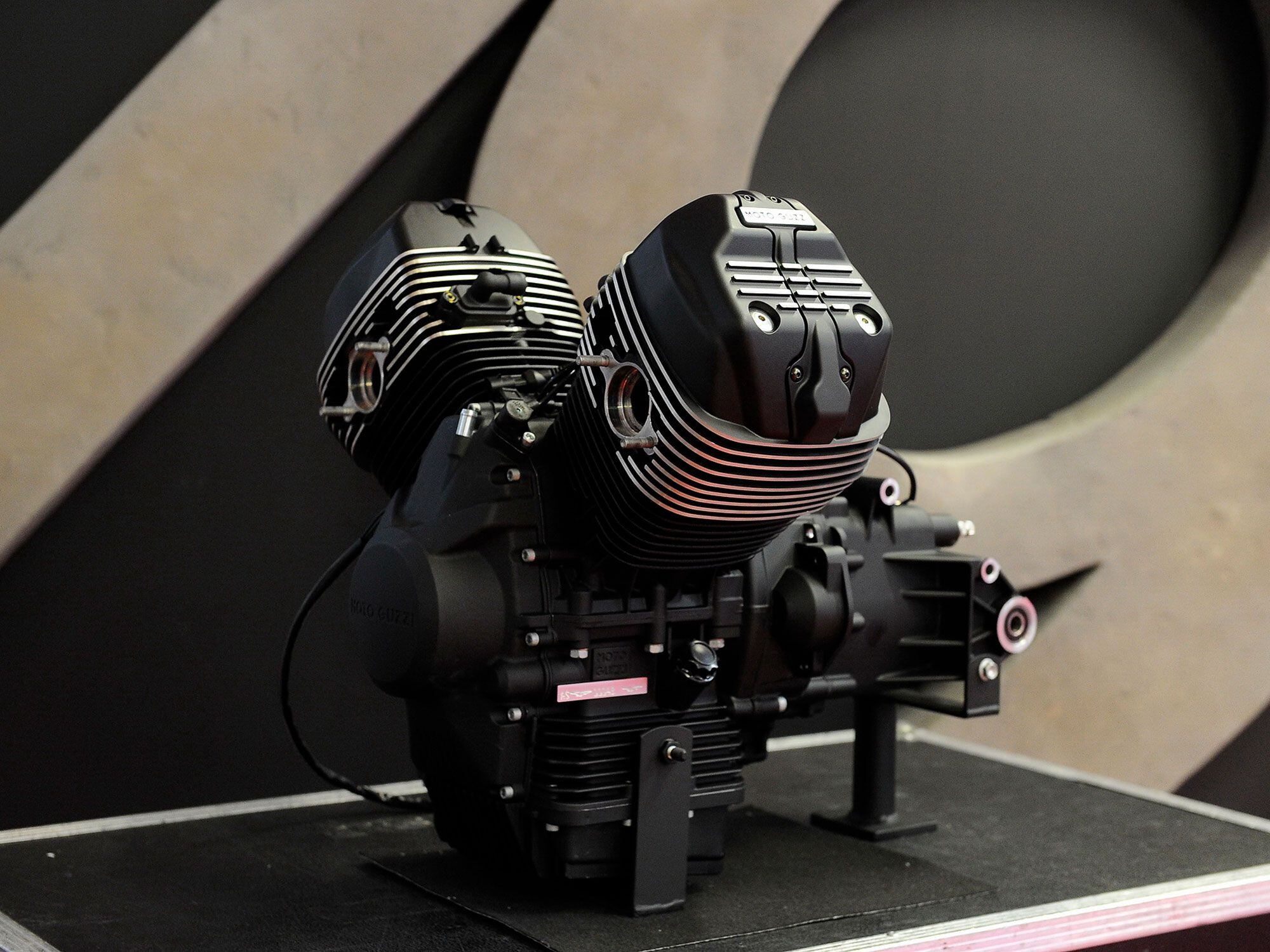

Moto Guzzi’s V2 Small Block has continually seen changes and refinement as the decades have passed, continuing to remain a staple of the fleet. (Bruno dePrato/)Moto Guzzi is one of the legends of motorcycling, a marque easily as respected and loved as Harley-Davidson. The manufacturer was founded in 1921, when shipowner Mr. Emanuele Vittorio Parodi, along with his son and air force pilot Giorgio, got together with Carlo Guzzi to found Moto Guzzi in Mandello del Lario. But this maker of inarguably desirable bikes went through some very hard times, especially after World War II, and has had to rebuild its legend over and over again.

The Moto Guzzi factory in 1921 in Mandello del Lario. (Moto Guzzi/)Just as Ducati had its foundational engineer in Dr. Fabio Taglioni, Moto Guzzi was blessed with the technical knowledge and motorcycle-industry experience one Dr. Giulio Cesare Carcano. Carcano created the best-performing Moto Guzzi racers and production models from the late 1930s through 1966, when he finally left the factory to which he had dedicated the largest part of his professional life. Dr. Carcano created winning single-cylinder Moto Guzzi racers, including the 350cc version that took Keith Campbell to the 1957 World Championship in the face of the much more powerful Gilera 350 Four, which could not counter a very light and agile single blessed by a very solid torque curve.

Keith Campbell in 1957. (Moto Guzzi/)On the opposite end of the Moto Guzzi racer range, Dr. Carcano created the 500cc V8. For production, he designed a whole range of ultra-reliable Moto Guzzi singles from 250 to 500cc. When Moto Guzzi bowed out of competition, Dr. Carcano turned to the development of new production models intended to pull the Mandello del Lario make out of the doldrums in which the Italian motorcycle industry was foundering. Their market had been cut into by, of all things, the then-new Fiat 500 subcompact, which was cheap enough transportation to compete with small- and medium-displacement motorcycles.

The 500cc V8 designed by Dr. Carcano. (Moto Guzzi/)To counter the 500, Dr. Carcano designed a 600cc, air-cooled, 90-degree V-twin that was more refined and much more powerful than the cheap parallel twin in the Fiat. The new 600cc V-twin was actually offered to Fiat as a prospective optional engine for a “sport” version of the 500. Tests were positive, but Fiat passed. Instead, they found a market in the Italian army, which had adopted Moto Guzzi’s Falcone 500 as their standard service motorcycle. They found the new compact V-twin was optimal for a half-tracked mountain vehicle, a sort of mechanized mule for alpine troops. Order numbers were limited, but adequate to start production and further develop and refine the engine that officially became the celebrated Moto Guzzi V7.

The V7 had a relaxed look that attracted traditional die-hard Moto Guzzi enthusiasts and that was reminiscent of the Harley-Davidson Duo Glide of the time. Three years later Dr. Carcano resigned as chief project engineer and Moto Guzzi hired Lino Tonti, who was not a certified engineer but known as a competent technician with a solid background. Tonti enlarged the V7 displacement to 750cc for the V7 Special, and then created the Moto Guzzi 750 Sport.

Moto Guzzi’s Small Block V2 has seen many changes, versions, and improvements since its introduction in the mid-’60s. (Moto Guzzi/)In 1973 Moto Guzzi was acquired by Alejandro De Tomaso, who had acquired Benelli the previous year. This began De Tomaso’s controversial adventure with the two makes. De Tomaso was no engineer, and supposedly hated engineers due to their understandable practice of criticizing his technical decisions. From then on half-baked projects were the order of the day. A Honda CB500 Four engine was taken apart and used for the creation of the molds for the Benelli 504 and, with the crude addition of two extra cylinders, of those for the Benelli 756. De Tomaso also requested that the Benelli 504 be downsized to 350cc in order to power the Moto Guzzi 354. That project failed badly in the face of the Honda 350, so Tonti stepped in to suggest that Moto Guzzi create a small 90-degree V-twin to capitalize on the positive image of the V7 model range.

But the Moto Guzzi “Small Block” V-twin was not to be designed by the technicians in Mandello del Lario. De Tomaso wanted it designed at De Tomaso in Modena, perhaps because he wanted to check each developmental step. But the De Tomaso Motor Company had effectively no one with significant engine design or engineering experience, as De Tomaso cars were powered by Ford’s legendary 351 Cleveland V-8. There had never been a De Tomaso-designed engine. As a result, nobody knows exactly who designed the original Moto Guzzi V-twin. Indeed, the initial project was not particularly well refined.

The first production version came in the form of a compact 350cc unit of moderate potential powering a neat-looking runabout. The new V-twin featured a solid horizontally split crankcase, a forged crankshaft turning on plain bearings measuring 39mm at the distributor side and 41mm at the clutch side, giving a crank throw of 38mm; cap-type connecting rods were adopted. There was also a centrally located camshaft, cylindrical cam followers, steel pushrods and rockers, two valves per cylinder, parallel and perpendicular to the head plane, and, finally, a Heron combustion chamber.

So far so good, except for the fact that the project was developed with no solid engineering guidelines. The combustion chamber design had been adopted on the basis of the success of the Moto Morini 350cc and 500cc V-twins, designed by Dr. Franco Lambertini, a Heron specialist. His Moto Morini 350-500 V-twin was easily capable of exceeding a specific output of 100 hp/liter, as Lambertini knew how to play the high-performance combustion-chamber-turbulence game. However, De Tomaso decreed that the new V-twin would adopt the leftovers from one of his worst marketing failures: the Benelli 254, a four-cylinder 250cc model that he had expected to conquer the compact bike segment. But the thing never worked right and had a mean tendency to seize pistons. The market rejected it and the project was almost totally scrapped, except for the con-rods, which were forced into the Moto Guzzi V2.

The V35 had 30 hp and 20 pound-feet of torque. (Mary dePrato/)With a 66mm by 50.6mm bore and stroke, the Moto Guzzi 350 V-twin could still swallow the short Benelli 254 rods, but the stroke-to-rod-length ratio was far from optimal and consequently secondary order imbalance was very high. Moto Guzzi introduced the new V35, announcing a power output of 30 hp at 7,800 rpm, but that was hard to believe in light of the claimed peak torque of 20.2 pound-feet at 6,500 rpm. In reality the Moto Guzzi V2 limped along all its life. Good engines come from neat engineering projects, not from patched-up “creations.” The factor that kept the unit alive in its original 350cc displacement was that the numerous model variations it powered were all rather pleasantly styled, with the exception of the short-lived 1987 V35 Florida custom. The V35 was fairly big and heavy for a 350cc-displacement engine, though the crankcase had proved one of the best points of the whole project, being capable of standing much higher loads.

The 500cc V50 edition was introduced in 1977 by increasing bore and stroke to 74mm and 57mm, respectively; with a compression ratio of 10.4:1 and fed by a pair of 24mm Dell’Orto carburetors, the engine was claimed to generate 48 hp at 7,500 rpm, but this again was hard to believe. Bore and stroke measurements aside, the engine design was basically unchanged.

The 500cc V50 Small Block was introduced in 1977. (Moto Guzzi/)And that includes the con-rods, still the Benelli 254 leftovers despite the increased stroke. This caused more than one reliability problem, since the cylinders were very short and the pistons traveled inside the unexposed segment of the barrel, causing the engine to become very hot when working at high rpm for extended time. The stroke-to-rod-length ratio problem was closed when the Moto Guzzi V2 was enlarged to 650cc by boring it out to 80mm and stroking it up to 64mm. The adoption of adequately sized rods, now measuring 120mm center to center, was apparent in the increased height of the cylinders, now featuring seven cooling fins in place of the previous three. At long last the beleaguered Moto Guzzi V2 Small Block got its rods right, finally bringing one of the most tragic and operatic episodes in all of Italian history to a triumphant and satisfactory denouement.

The largely revised 650cc version of the engine was slowly emerging as the real lightweight partner to its larger brother, which had in the meantime grown first to 850cc and then to a full 1,000cc displacement. With a properly proportioned crank assembly, the 650 was smoother and more reliable. Fed by two Dell’Orto PHBH 30 carburetors and with a 10:1 compression ratio, the V65 was claimed to deliver 52 hp at 7,050 rpm with a 40 pound-feet of torque peak at 6,000 rpm. Given the moderate weight at 368 pounds, the new V65 turned out to be a gratifying tourer with a top speed in the region of 115 mph and solid throttle response from 3,000 rpm up.

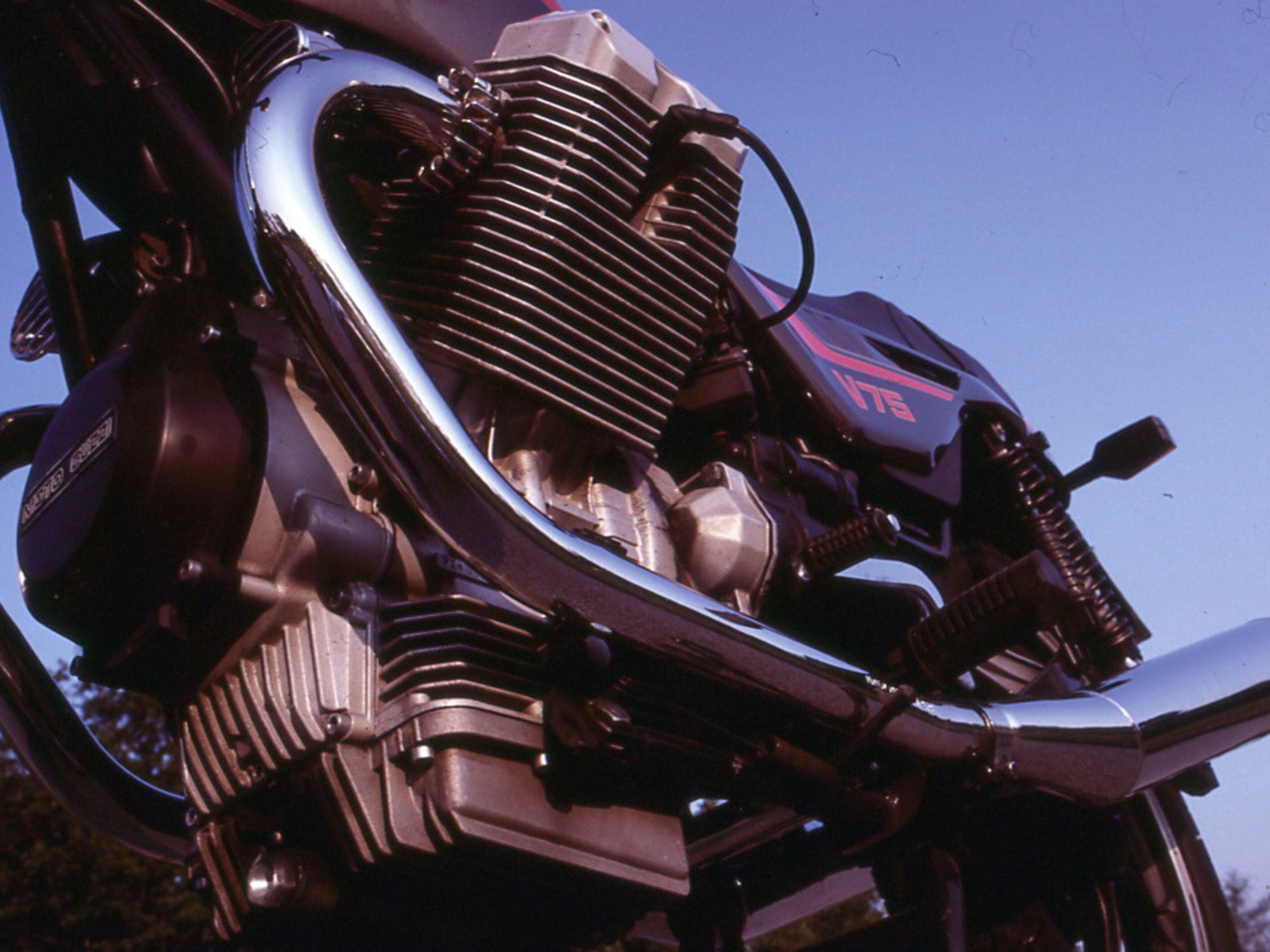

Moto Guzzi developed a number of model variations around the V65 unit, including fully dressed custom touring bikes that enjoyed a mild success with the public. The V65 Lario was expected to set a solid mark in the domain of the intermediate-displacement sportbikes, as it was a neat-looking bike powered by a special four-valve edition of the V65 twin.

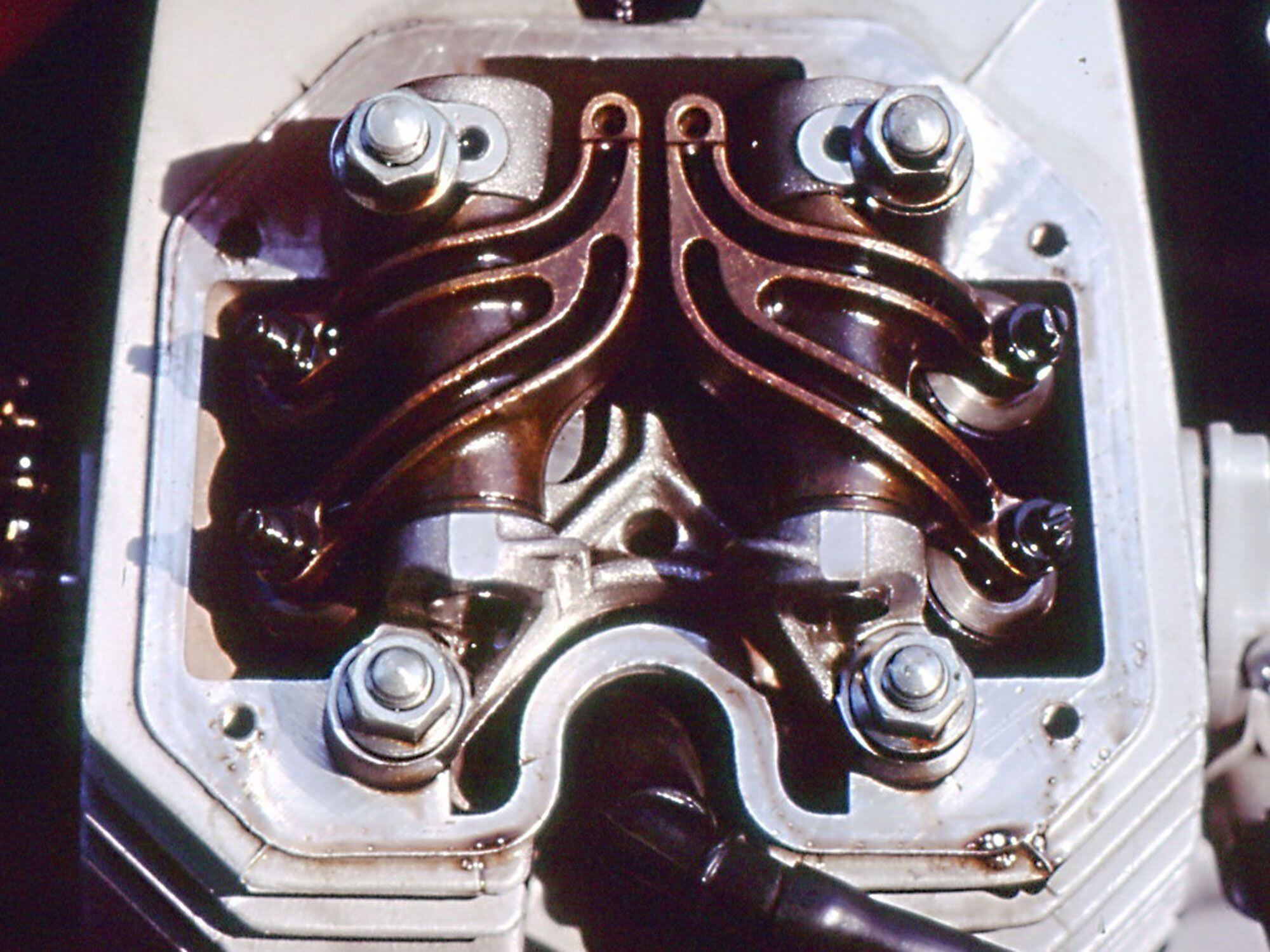

Riding the V65 Lario in 1984. (Mary dePrato/)There was much cheering at the unveiling of the V65 Lario at EICMA 1983. The motorcycle promised to renew the myth of the V7 Sport. But not so fast; the four-valve V-twin featured the same basic valve train, featuring cylindrical tappets, pushrod, and sleeve-type rockers crowded inside the heads. Moto Guzzi claimed 60 hp at 7,800 rpm and 40.1 pound-feet of torque at 6,000 rpm. The Lario went into production in the second half of 1984…and had disappeared by the end of 1985. The valve train was so oddly put together that the relationship of the pushrods and rockers was all wrong, causing flexing that developed awful frequencies at higher revs, destroying the valves and, as a consequence, the pistons as well.

The four-valve head of the V65 Lario was an overcrowded mess that destroyed valves due to flex and vibration at higher revs. (Bruno dePrato/)Moto Guzzi went back to the traditional two-valve heads on the V65 and on the subsequent V75, an engine that was regarded as being at the displacement limit for the unit. The V75 debuted in 1989 as a stroked V65, featuring the same 80mm bore with the stroke grown from 64 to 74mm. Moto Guzzi finally claimed a credible 45 hp at 6,800 rpm from a unit with a compression ratio of 9.7:1 fed by two PHBO 30 Dell’Orto carburetors. Peak torque was a moderate 43.8 pound-feet, but at only 3,200 rpm. In 1989, the four-valve heads resurfaced for special editions of the NTX enduro model intended for the Paris-Dakar rally, but the attempt never reached its target.

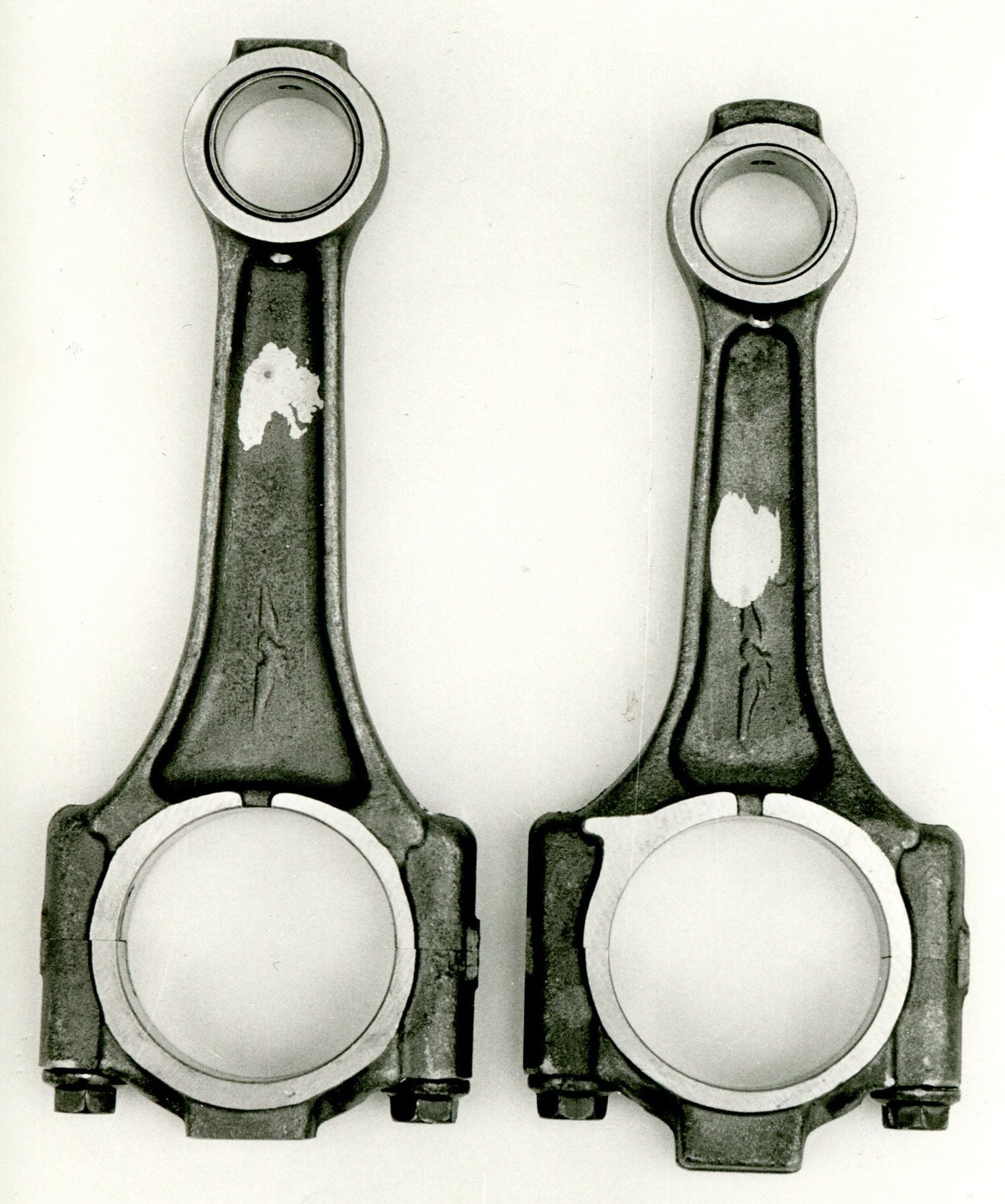

A longer V75 connecting rod (left) next to a V65 rod. (Bruno dePrato/)Meanwhile, Moto Guzzi suffered an undeniable decline throughout the ’90s due to an increasingly erratic management from De Tomaso. This finally ended when Moto Guzzi was acquired by Ivano Beggio’s Aprilia Group, but things did not immediately improve at Mandello del Lario. Beggio and his team were focused on the models powered by the “Big Block” V-twin, and the V75 was merely restyled into the Breva V750 runabout. The engine evolved from carburetors to fuel injection with a slight power increase to 48 hp at 6,200 rpm. The Breva V750 was styled smartly, maybe even too smartly for a Moto Guzzi, and its 750 V-twin delivered 41 hp. The chassis was new and featured a radical steering geometry that received controversial comments due to a steering axis set at 28 degrees.

For beleaguered Moto Guzzi the real turning point came in 2004, when the Piaggio Group acquired the whole Aprilia Group and Moto Guzzi with it. The Piaggio engineering team took the V75 apart and duly analyzed it, while the styling department decided to adapt the most classic V7 750 Sport styling to the 750cc, small-block, V-twin-powered V7, setting the stage for the V7 Classic.

The Breva V750 was a departure in styling for Moto Guzzi. (Moto Guzzi/)In 2012 the Euro 3 emissions regulations came into force and the engine received the first of a series of fundamental upgrades. The Piaggio technicians developed a new induction system featuring a single 38mm throttle body and a Y-shaped inlet manifold. The combustion chamber kept the Heron-type design, but new higher-quality pistons allowed a compression ratio bump to 10.2:1. Peak power of 48 hp at 6,200 rpm and 40.3 pound-feet peak torque at 5,000 rpm were claimed; the new induction system and higher compression ratio definitely generated a much flatter torque curve, and the engine performed smartly in all road tests.

At this point let me say that I still wonder why the Piaggio technical team did not try to improve the 750 V-twin by analyzing and evolving the design of the Heron chamber to improve its turbulence game. The 80mm bore would allow plenty of opportunities to reposition the valves, which were aligned on the main diameter of the bore with the inlet runner coming in straight. This did not result in the conditions needed to generate the proper swirl turbulence necessary for a Heron combustion chamber to deliver optimal combustion and maximum efficiency. The Heron design requires strong, well-managed turbulence more than other combustion chamber configurations. The Moto Guzzi technicians had only to take a look at the Heron combustion chamber of the Moto Morini 500 V-twin that was then delivering 48 honest horsepower. Perhaps Piaggio was already thinking of its next hemi head.

The 2019 Moto Guzzi V7 III Racer. (Moto Guzzi/)The new hemi head debuted in 2016 in order to bring the engine in line with the new Euro 4 regulations, and may represent the ultimate evolution for the Moto Guzzi Small Block V-twin. The head was just the beginning of the final evolutionary process. In combination with the new head, the displacement was increased to 853cc by enlarging the bore to 84mm and increasing the stroke to 77mm. To fully comply with the Euro 4 regulations, the new head incorporated a secondary air circuit to more thoroughly treat the exhaust gases in the catalytic converter. The valve train was revised by fitting the tappets with roller-type cam followers, which not only reduced the frictional losses but allowed the use of more advanced cam grinds. The new cams feature fairly high lift and very short overlap to drastically reduce the emission of unburned hydrocarbons.

The combustion chamber features a compact hemi profile with the valves set at a 56-degree included angle. The valves measure 40.5mm for the inlet and 35.5mm for exhaust, much larger than those of the V7 Heron, which were 33mm and 29mm, respectively. Despite the larger valves, the combustion chamber profile includes a neat annular squish area for a better control of turbulence. Compression ratio is a solid 10.5:1, same as on the V7. The V9 still breathes through a single 38mm throttle body and Y-shaped manifold. Power went up to 55 hp at a moderate 6,250 rpm and 45.7 pound-feet of torque at 3,000 rpm. These numbers underline the great flexibility of the new engine and its ability to deliver positive performance forth from Mandello del Lario unto the very ends of the Earth. A new larger-diameter single-disc dry clutch was adopted, along with a new final transmission featuring a shaft drive with two U-joints for much smoother functioning.

The V9 was just a safe step to reach the ultimate target. Enter the V85. The V85 is what the Moto Guzzi Small Block V2 should have been from the beginning, not in terms of the displacement, but in the rigorous engineering and research applied to the whole project down to every last component. Never mind, for once, the bore and stroke numbers; the V85 is an even more radical evolution of the first-edition V9.

To achieve much higher power numbers it was necessary to make the engine reliably rev much higher. Therefore, Piaggio technicians have recalculated the crankshaft, slightly increasing the diameter of crank and main end journals and related bearings, now measuring 40mm and 43mm on the distribution and clutch sides, respectively, up from the previous 39mm and 41mm. Crank throw diameter has also been increased, from 38mm to 40mm. The resulting crankshaft is more than adequately strong and rigid, even in combination with the V9/V85 77mm stroke, since even here the main and the crank journals overlap by a few millimeters at both ends. The lubrication system has further evolved with the adoption of a semi-dry sump and two pumps. The sump received larger cooling fins to improve oil cooling. This way there was no need to add an oil cooler. An accurate study addressed to improve the crankcase ventilation and reduce oil splashing further improved the reliability of the whole lubrication system and the mechanical efficiency of the new unit.

The first-edition Euro 4 homologated V85 TT unit delivered 80 hp at 7,750 rpm and 59 pound-feet of torque at a moderate 5,000 rpm. Now the unit has been updated to the Euro 5 standard with no change to displacement and still delivers 78 real horses—a remarkable result.

The Moto Guzzi V85 TT. (Bruno dePrato/)To become the new V85 TT, the V9 was redesigned in all the major components. The rods come from new forgings and are reportedly lighter and stronger. They still measure 130mm center to center, which—as careful readers will no doubt realize by now—is a little on the short side in relation to the 77mm stroke. Piaggio technicians wanted to keep the engine as compact as possible, though at the possible cost of higher secondary-order imbalance. The valve train was completely recalculated both in cam grindings and the structure of cam followers, pushrods, and rockers. Pushrods of various structures and made from a variety of materials were tested to obtain the most stable and reliable transfer of the exact lift from the cam profile to the valves. Finally, solid pushrods made from high-tensile aerospace aluminum alloy 7075 were selected for their low inertia and the positive results they granted in terms of performance and reliability. To obtain the highest possible volumetric efficiency from a two-valve design, a 47mm titanium inlet valve was adopted. The V85 breathes through a 52mm central throttle body and related Y-shaped manifold.

The last step in the evolution of the Small Block is the V9. This is not an upgraded edition of the previous V9, but rather a more accessible edition of the V85. Piaggio technicians have distilled that engine into a new general-purpose unit intended to deliver a substantial increase in performance level while keeping the price competitive.

Moto Guzzi’s Small Block V-twin evolution is represented by the new V9. (Moto Guzzi/)The cylinder head retains the layout of the V85 unit, but the inlet valve is stainless steel, the central throttle body is 38mm in diameter, the cams have milder profiles with almost no overlap, and the pushrods are steel. Yet the new V9 delivers a claimed 65 hp at a moderate 6,800 rpm, 10 hp more than the previous version. More remarkable is an improved torque curve, climbing from the previous claimed 45.7 pound feet at 4,000 rpm to 53.8 at 5,000, a clear improvement. In order to make the V9 both more accessible and more competitive, Piaggio decided to drop the crankshaft’s traditional forged one-piece construction (though this is retained in the V85) and adopt a press-fit crank assembly with one-piece con-rods. The new crankshaft features a slightly leaner crank throw, 38mm in diameter instead of 40mm for the solid forged unit, but Piaggio says the assembly remains fully reliable due to proprietary technology developed to ensure a very solid and stable assembly.

Gone is the 750cc version of the Moto Guzzi Small Block V-twin. Production will focus solely on the 853cc engine. The V7 and V9 models differ only in styling, with the V7s retaining their classic and very elegant look and the V9 more along the lines of a custom. Moto Guzzi celebrates its 100th anniversary in 2021, and to make the celebration memorable, a totally new V-twin will be unveiled, displacing at least a liter and featuring liquid-cooling and four valves per cylinder. Given the performance achieved by the V85 TT unit, chances are that the Moto Guzzi Small Block V-twin will remain in production for years to come. One still hopes that someone in the marketing department will see the light and a V85 Sport will become reality, perhaps in metallic light green with a red frame holding the best available components. Motorcycling is made of special memories, passionate dreams, and perfect replicas that revitalize immortal models by applying solid but invisible technological updating.

-

Despite having less peak horsepower, the 2022 Hayabusa is quicker than the previous generations. (Suzuki /)The Suzuki Hayabusa is unusual in sports motorcycling in that it has not been constantly updated. After its 1999 introduction, it quickly became the machine of choice for serious 3 a.m. pink-slip riders and other seekers of ultimate acceleration and top speed. This unusually styled bike is the one to which super turbo kits are often added in order to give the rider 650 hp or more, on the time-honored principle that too much is never enough.

A second-generation Hayabusa came in 2008, with a jump to 1,340cc from the original’s 1,299cc, but otherwise this is a bike which has not really participated in the electronic rider-aid revolution. That revolution began with the digital flight controls developed for the Apollo program, which put astronauts on the moon. It then moved quickly to military and then commercial aircraft, then to Formula One racing cars, and finally to MotoGP bikes. Now that it has become a normal part of any powerful production bike’s suite of functions, it’s time for its adoption on the Hayabusa. With it come other electrically powered updates such as LED lighting, CAN bus controls, and TFT LCD instruments. Suzuki says its new bike has “550 new or redesigned parts.”

Torque, Tuning, Electronics

Emissions standards continue to tighten, and the latest set that bikes must meet in order to be widely sold is Euro 5. The easy reductions in carbon monoxide, unburned hydrocarbons, and nitrogen oxides were in the past achieved mainly by more accurate mixture control, with the shift from carburetors to digital fuel injection, and after-treatment, by passing exhaust gas over hot catalyst-bearing surfaces to accelerate desired chemical changes. Euro 5 now directly impacts engine design, because compliance requires reducing emissions at their sources inside of engines.

Through the necessary changes, any performance lost was more than made up for by the adoption of such acceleration-boosting electronic improvements as throttle-by-wire, traction control, and anti-wheelie systems. This third-gen ‘Busa’s claimed 3.2-second 0-60-mph time is superior to gen 1’s 3.3 and gen 2′s 3.4 seconds. The same is true of 1/8-mile times: compare gen 3′s 6.8 to the 7.1 and 6.9 seconds of the previous bikes. Add to this the substantial torque gains achieved in gen 3 over the range of 3,300 rpm to 7,000 rpm and you have a bike of superior rideability that has gained rather than lost performance in meeting Euro 5.

The addition of throttle-by-wire, traction control, launch control, and anti-wheelie has made the 2022 Hayabusa quicker without massive changes to its engine. (Suzuki/)Some pundits had expected another displacement increase, possibly by boring Hayabusa’s 81mm cylinders to 84mm to increase displacement to 1,440cc. This was believable because one way to meet emissions is to detune slightly, then recover the lost power with a displacement increase. That didn’t happen; Suzuki engineers were able to turn some of the changes Euro 5 requires, such as reduced valve overlap and combustion chamber details, into benefits. They came up with as much as a 16 percent boost in torque in the 3,300–7,000 rpm range, the part of the powerband actually used in most street riding. Yet if the Little Old Lady From Pasadena throws down the gauntlet of challenge, top performance is, based on the numbers provided, better than ever. That has transformed a traditional peak-power torque curve, which gains on top by using cam timings that give away some torque lower down, into something more like the flatter, more rideable curves we are seeing on recently designed parallel twins. We can call this new trend “Euro 5 torque flattening.”

Durability

Many a Hayabusa is operated under extreme duty conditions, and this bike will support a very large aftermarket of performance-enhancing parts. Therefore engine durability must from time to time be enhanced by changes that support the Hayabusa’s reputation of being able to handle four or more times its original horsepower. Hayabusa engines are regularly used for racing and record-setting on four as well as two wheels. They are chosen because of their reputation for standing up to extreme turbocharging. Accordingly, a suite of durability-related engine changes has now been made.

Suzuki has made some durability-related engine changes to the already legendarily robust GSX1300RR engine. (Suzuki/)Styling

Another category of change is style, but in this respect Hayabusa has proven ageless. While other sportbikes conform to the 20-year-old “shock-wave supersonic look” of sharp edges, dart-like shapes, and scoops, the Hayabusa’s theme has been a complete contrast: functional aerodynamics that works. Suzuki claims that Hayabusa, despite its substantial size, remains among the three production bikes with the lowest CdA (aero coefficient times frontal area). That means smooth, organic curves that remind me of Britain’s Hawker Hunter, a largely subsonic fighter of the 1950s. Suzuki is wise not to change a look that gives instant recognition—no other bike has it. As a footnote, when it comes to top speed, all generations of Hayabusa have been voluntarily speed-limited to 300 kph, or 186 mph.

The 2022 Hayabusa is still easily recognizable with its smooth, flowing organic shape that gives it one of the lowest CdA numbers in motorcycling. (Suzuki/)Chassis and Handling

Chassis changes are inevitably required by the constant advance of tire and suspension performance. While it’s true that most riders never exceed tire limits, grip is there to be used and therefore chassis design must advance to make that possible. KYB suspension and Brembo Stylema brake calipers are just the most visible changes.

Suzuki’s press release on the gen 3 does not reveal the final drive ratio, which was 43/18 on the last generation. If it has in fact been changed to boost acceleration, that might explain why claimed fuel mileage in gen 3 is 35.1 mpg compared with the 41.4 of gen 2 (an 18 percent increase). Spinning the engine faster by gearing it down can increase acceleration, but friction loss increases with rpm, possibly increasing fuel consumption. It’s no biggie; if you can afford the bike, you can certainly afford its fuel. But it does make me curious as to whether the sprocket ratio has been changed.

Greater tire and suspension performance required Suzuki to increase the Hayabusa’s handling capabilities. (Suzuki/)In the days to come we will discuss in greater detail the major categories of change that define this new Hayabusa: engine durability, engine performance, emissions, and chassis.

-

Benelli looks to be coming back to the sportbike arena soon with a restyle of its entry-level 302R. (Benelli/)We’ve yet to see any significant launches from Benelli for 2021, but the company has been busy developing new models that are sure to be officially revealed soon. One of them will no doubt be this new 302R baby sportbike based on the engine from the naked 302S.

RELATED: 2015 Benelli BN 302 FIRST RIDE Motorcycle Review- Photos- Specifications

While Benelli has made a 302R before (the number reflects its 300cc, two-cylinder configuration), and the old version remains on sale in some markets, it’s a dated-looking bike these days. The new version, seen here thanks to published type approval documents despite the fact it’s yet to be officially unveiled, solves that problem with entirely new bodywork, though the chassis and engine beneath are largely unaltered.

Beneath the refreshed bodywork, mechanics should be similar to this current 302S naked model, with ABS included. (Benelli/)The styling starts with a vertically stacked pair of headlights, perhaps a nod to the design of the Tornado Tre that marketed the rebirth of the Benelli brand at the turn of the millennium. The light unit is set into a nose that manages to look slimmer than before by featuring separate side sections to reduce its visual mass and create mock air intakes with LED light strips inside. Further down, the side panels are actually much the same as the previous version, though new graphics and the addition of black paint to the lower section help make them look less bulky than before. It’s a similar story with the fuel tank, which retains the same uncomfortable combination of creases and bumps as the old 302R. Behind it, the seat unit is completely new, with some hints of KTM in both its orange paintwork and the use of flat surfaces and sharp creases.

RELATED: Benelli Motorcycles FIRST LOOK Motorcycle Review, Photos

Mechanically, the bike appears to be largely unchanged. It’s got the same steel tube frame as the old 302R, and the engine is still a 300cc parallel twin. Power is actually down a fraction, from 38 hp to 35 hp, probably due to emissions-related internal changes, but fortunately the new bodywork is also lighter than before—giving a fully fueled curb weight of 182 kilograms (401 pounds) compared to the old version’s 190 kilograms (419 pounds).

The 1,410mm (55.5 inches) wheelbase is unchanged and the suspension looks to be the same as before, but Bosch 9.1 ABS has been added to the braking system to bring the bike into line with European regulations that make antilock brakes mandatory on new bikes over 125cc. As with the rest of Benelli’s new models for 2021 and 2022, we’re still waiting on official information and details about which bikes will be sold in the USA, but the new type approval means there’s no doubt that this machine is heading for production soon.

-

-

Hello Foss,

Welcome to The Motorbike Forum. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask.

Why not tell us a bit about yourself too.

Triumph’s Prototype TE-1 Electric Motorcycle

in Motorbike news

Posted

A drawing of what Triumph’s prototype TE-1 electric motorcycle could end up looking like. (Triumph/)

The Triumph TE-1 electric sportbike you see here is not just another hasty “Grainger catalog” electric project of the kind we’ve so often seen. It is based upon a suite of new technologies and the collaboration of five separate organizations. TE-1 combines a state-of-the-art liquid-cooled electric motor, a high-efficiency power supply based upon the new silicon carbide (SiC) switching technology, and a novel battery concept claimed to permit a 37 percent increase in energy density for a target power density.

Over many years Britain’s “Formula One zone,” centered around Banbury, 60-odd miles northwest of London, has provided championship-winning engine and chassis technologies to F1 builders. In the past decade much innovation has been focused on vehicle energy recovery and management by means of electric motor-generators, advanced battery or capacitor systems, and highly efficient power supplies. Someone has understood that these technologies and the workforce skills that create them can also make real contributions to the design of zero-emissions electric vehicles for commercial sale.

The Triumph TE-1′s motor, power supply, controller, and frame. (Triumph/)

As you can see from the high quality of TE-1′s parts, this is a prototype and not a vehicle ready for production. For that reason, no specifications or performance figures are supplied.

This project began in May 2019 and was funded by BEIS, the Department for Business, Energy, and Industrial Strategy, and the Office for Low Emissions Vehicles (OLEV), both of the British government. The participants are:

The stated purposes of this two-year TE-1 project are:

The Technologies

Recent Formula One rules have sought to interest the auto industry in the series by incorporating advanced energy recovery, storage, and use schemes in parallel with the traditional internal combustion engine. The goal, for both F1 and automakers, is greater fuel efficiency. Emerging from this work have been electric motors, power supplies, and batteries of lighter weight and higher performance—just what’s needed to produce a more satisfactory electric motorcycle.

Motor

As an electric motor operates, resistive losses in its windings appear as heat. In many electric vehicle projects, when motor temperature rises high enough to threaten the integrity of wire insulation, power is automatically reduced until the motor cools.

RELATED: Battery Technology Goes 3D

A better solution is to use the circulation of liquid coolant to remove resistive heat as it is produced. In this way, temperature can be controlled without requiring power reduction. This is accomplished by having motor windings stationary, allowing them to be easily liquid-cooled, while a permanent-magnet rotor spins.

The Integral eDrive motorcycle and inverter placed next to a pint glass for scale. (Triumph/)

Because very high electric currents are required by high-power motors, the weight of copper conductors becomes significant. This makes it sensible to closely integrate the SiC power supply with the traction motor. High-performance electric motors are extremely powerful for their weight, each pound now able to deliver several horsepower.

Power Supply

Silicon carbide (SiC) semiconductor switching is now replacing the previous IGBT (transistor-based) silicon technology in power supplies. What the power supply does is to generate a rotating magnetic field that pulls the permanent magnets of the rotor around with it. The rotating field is kept in step with the rotor by an angular encoder. Previous switching technology provided power supply efficiency in the range of 90 percent, but the new SiC switching has shown it can provide a plateau of 98.5 percent efficiency. Reduced loss translates to increased vehicle range. Electric motor torque can be finely and quickly modulated.

Battery

Although discussion of alternatives continues, lithium-ion (li-ion) remains first choice as the basic battery technology for electric vehicles. Within the category, however, there are different electrode chemistries, each biased toward different aspects of performance. What WAE has done is to combine two cell chemistries, one favoring high energy density (as in cellphones) and the other, high power density (as for high-amperage applications such as power tools).

Paul McNamara, WAE technical director, has said, “The two types of cell have to be separated and controlled with a DC-DC converter between them.”

RELATED: Technology Validated In The Showroom, Not On The Racetrack

By carefully managing charge movement from one to the other, a better overall compromise between high energy and high power is achieved.

When asked if the rise of EVs could bring a lot of jobs and revenue back to the UK, McNamara replied that cell manufacture will stay in low-cost locations but that sophisticated control and management can be the UK’s forte.

The Motorcycle Itself

Triumph, whose 765 Triple engine now powers Dorna’s Moto2 field, and whose production machines are well respected, can be relied upon to provide a practical state-of-the-art vehicle free of the basic errors we have seen in some projects. As you can see from the photos, it is styled to resemble existing conventional sportbikes, distinguishable from them mainly by having no exhaust system.

The TE-1 will be distinguishable from its Triumph ICE counterparts by the lack of exhaust pipes. (Triumph/)

Contradictions and Inconvenient Realities

The last time the British government was this friendly to the motorcycle might have been the immediate post-World War II period, when the Board of Trade required that motorcycle producers export at least 70 percent of their production as a means of acquiring overseas currencies “harder” than the beleaguered pound sterling. The original Triumph firm became economic heroes by shipping impressive numbers of bikes into the vehicle-hungry and flush postwar US market.

RELATED: Price: Marrying high technology with affordable motorcycles

Much as we want to see such projects go forward, we wonder if they can buck the tide of history and the realities of elected government. To “create jobs and a talent base” is a noble ambition, but we know that Triumph Hinckley has just offshored its production to Thailand. I suspect the reason for the move is less the attraction of lower wages than that manufacturing is easier to accomplish in a manufacturing nation. Thailand is a growing manufacturing economy, with much to offer: banking, accessory suppliers, and a trained workforce in being. England, by contrast, has been deindustrializing for decades, losing shipbuilding, aircraft manufacture, and much of its auto production.

The Triumph TE-1′s prototype liquid-cooled motor. (Triumph/)

Government funding “to grow the UK economy through science and technology” has the ring of bold initiative but may last no longer than until the next general election. England (and indeed most countries in which people can vote) has a long history of ambitious projects begun by the party in power, which at the next change of leadership are canceled and replaced by entirely other projects. Britain’s TSR-2 aircraft, Black Arrow satellite launcher (a single satellite was launched), and Blue Streak IRBM are notable examples.

When potential investors are shown prototypes exclusively made by expensive means such as CNC, they know they are looking at a one-off rather than at hardware that is close to production, employing parts produced by volume methods.

Despite these qualifications, seeing new developments that open fresh possibilities is always positive, and we can hope that all participants in the TE-1 project will find it rewarding. We hope to soon see public demonstration of what the new technologies integrated into TE-1 have accomplished.

View the full article