-

Posts

2,281 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Events

Store

Gallery

Community Map

Everything posted by Mickly

-

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

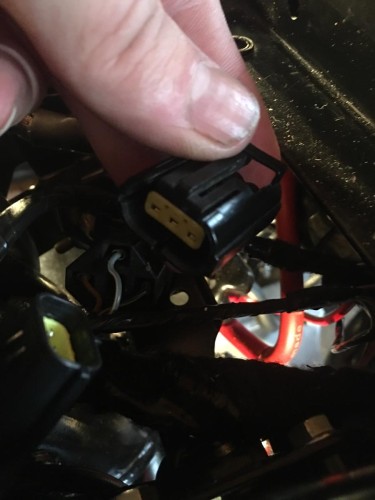

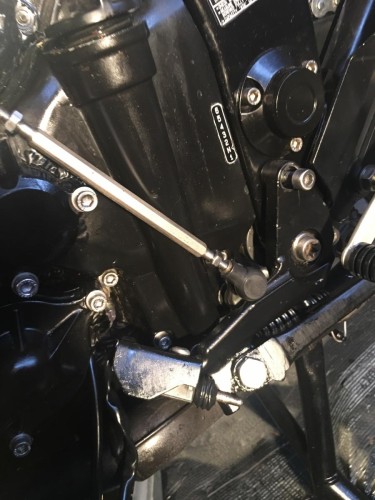

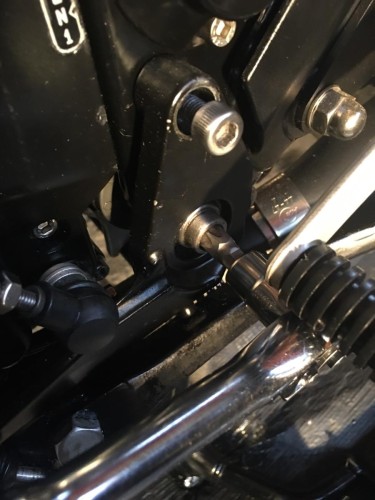

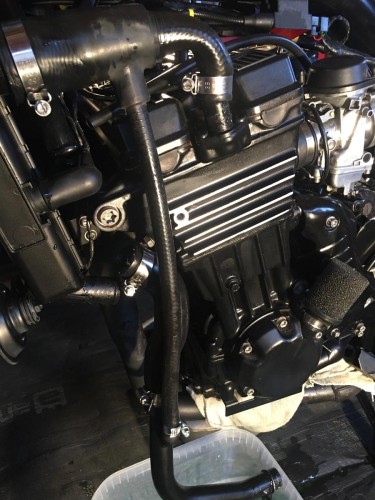

Right the side stand needs to be removed next. Top side stand bracket mounting removed Side stand switch connector undone Gear change linkage rod undone & moved to allow access to lower engine mounting bolt that also holds the side stand Lower engine mounting bolt removal - what Haynes don’t say is that you need 6” long fingers & the dexterity of Dynamo to get to the nut at the back. It’s hidden by a plastic plug. And remove the side stand .... but no, what Haynes failed to say is that the harness routes behind the water pump & the bloody connector doesn’t fit through the gap !! Water pump loosened & withdrawn a tad releasing the connector, also need to remove the water pump upper hose cover to wiggle the water pump out. Water pump Hose Cover Side stand removed & stored in an old shoebox. Hose cover wrapped & put with tin with other fixings ( danger of this turning into a biscuit thread ) Watch this space ( or not ) for the next instalment.... removing the exhaust oooooooh -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

Cooling fan switch disconnected Cooling fan harness disconnected Horns disconnected - both sides ( Not standard fitting point, but looks ok on the radiator) Bottom fixings removed ( Both sides ) Top Fixings removed ( Both sides ) Radiator is free .... Oh no it’s not says law of Sod!! The fan harness is hooked up & you’ve forgotten the expansion tank hose !! Radiator off, emptied, wrapped in an old tablecloth & stored with the tank. Keep meaning to get some gloves when doing this kind of thing -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

No worries about you sharing it, I’m not on Facebook so unfortunately can’t partake of their wisdom, If I get stuck would you be ok to pass on a few Q’s ? -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

-

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

Lowest point of the cooling system ( looks nothing like the pic in the Haynes manual. Needs this bracket undoing from the block to separate the hose. Again not in the Haynes !! -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

-

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

-

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

Engine oil filler cap removed to allow sump to vent. Oil drain plug Oil ... I added new oil and it certainly didn’t go in that colour !! Can’t see evidence of water ingress & it’s not milky, more burnt, probably caused by the over heating due to lean fuelling. -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

Tank off, fixings bagged & taped to it. Wrapped in an old clean sheet & into the cardboard box it came in. -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

Fuel hose off - bit of wooden dowel with tape round it shoved in the end to stop any MORE fuel spilling out - doh !! At least I had some rags down to catch it this time!! -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

Air filter pods off so I can get to the fuel tap / fuel hose clamp. That green box has had a good wash out as it will house the carbs when they come off. -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

Thanks for the offer I may well have to take you up on that. Not sure until I get into it .... mate of mine has pointed out that I might be able to fit Triumph 955 pistons and liners and take it to 1275cc .... bloody git, now he’s planted that seed I might have to give it proper consideration. Hopefully it’s just a hone & new rings, but as you know, it could be a whole different ball game. -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

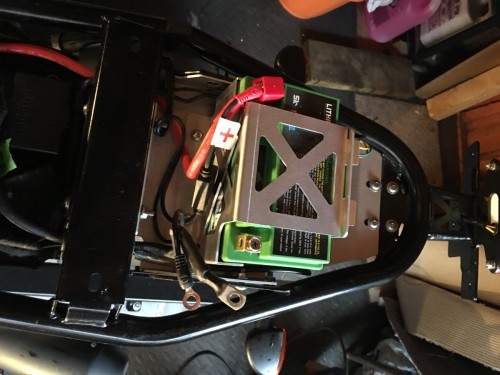

Seat unit off ( bubble wrapped & stored with its fixings taped to it) & -ve battery connection undone. -

Triumph Trophy Engine Strip

Mickly replied to Mickly's topic in Old Motorbikes, Projects and Restorations

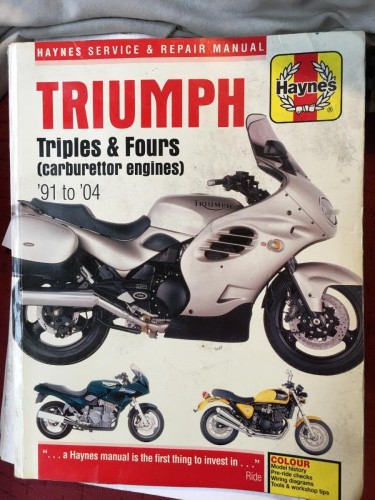

So here is the bike in a dingy but relatively dry Coventry garage. And armed with the Haynes Manual as a guide I will commence. According to the manual could do this without removing the engine but having spilt petrol over it It needs repainting, so out it will come & onto the bench. Which will require a little tidying first. -

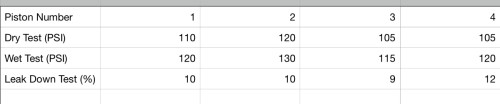

Right here goes, I will attempt to document the strip down & diagnosis, believe me, it won’t be as quick as Fastbob’s sterling ER5 job. The reason I’m doing this is that the Trophy went to a local workshop to have the fuelling sorted as it’s got after market pipes & foam pods instead of an air box. However it was diagnosed with a slipping clutch, oil leak ( only under load) & 59BHP - mainly due to the clutch slip. I then got them to do a compression test & this was the result: While the leak down test results weren’t too bad, the compression should be around 150psi, also there was only a small uplift between dry & wet tests. Armed with this information I’m going to have a look inside the engine & see what’s going on.

-

Sorry, I lost interest at “rules”

-

You’ll find rude is one of this forums premium qualities. They can sandwich rude into anything, it’s a skill set. Someone will be along in a minute to slate this reply, it’s part of the.. of the... umm it’s part of something, dunno what mind you... urr stress relief for the repressed? Log on, call someone a w*nker, the OP applies their finest witty repartee usually along the lines of “you’re a tw*t” Job done, everyone happy. Next topic Would you care to provide some specific examples of this type of insult trading . Pick any post exchange between [mention]Six30[/mention] & [mention]XTreme[/mention]

-

You're not meant to drink it. Hahaha, I’m not stupid... I took it intravenously

-

Did nothing for my athletes foot !!

-

I take great delight at waving / nodding at groups of classic scooter riders - in full parka / fox tail regalia & groups of Harley riders in full SoA uniforms

-

Didn’t there used to be an inferior Bike Forum called Nodding Dogs? Think it disappeared up it’s own sphincter due to crap Moderation & the poor quality of the members

-

Thanks for the advice. Having phoned a friend ( the guys who did the compression testing) they recommend taking off the sump & oil feed pipes then the engine will result flat on the bench. Hopefully picking the bike up on Saturday and will make a start on removing the engine soon after. I may start a new thread documenting my ham fistedness & give you all a good laugh !! Least it’s something to do over the next 4 weeks

-

Thanks for that @fastbob I should be able to knock up something like that with some angle iron & a few bolts No worries . Am I right in thinking that your upper crankcase and cylinders are all one casting ? Am I also correct in assuming that in order to remove the pistons you have to first remove the crankshaft ? Rather you than me . I fear you are correct, gonna try all options before having to do that!! Not that I know what options I have with low compression, the engine has only done 28k but has been standing for a long time. Could be gummed rings? Hopefully that can be checked by just removing the head.

-

Thanks for that [mention]fastbob[/mention] I should be able to knock up something like that with some angle iron & a few bolts

-

I’ve had that a few times as well